3D technology is a type of production with almost the greatest number of different customers. Our clientele is made up of a wide variety of industries, from engineering to fashion or even music. 3D scanning and 3D printing can be easily and quickly applied even in the production of musical instruments.

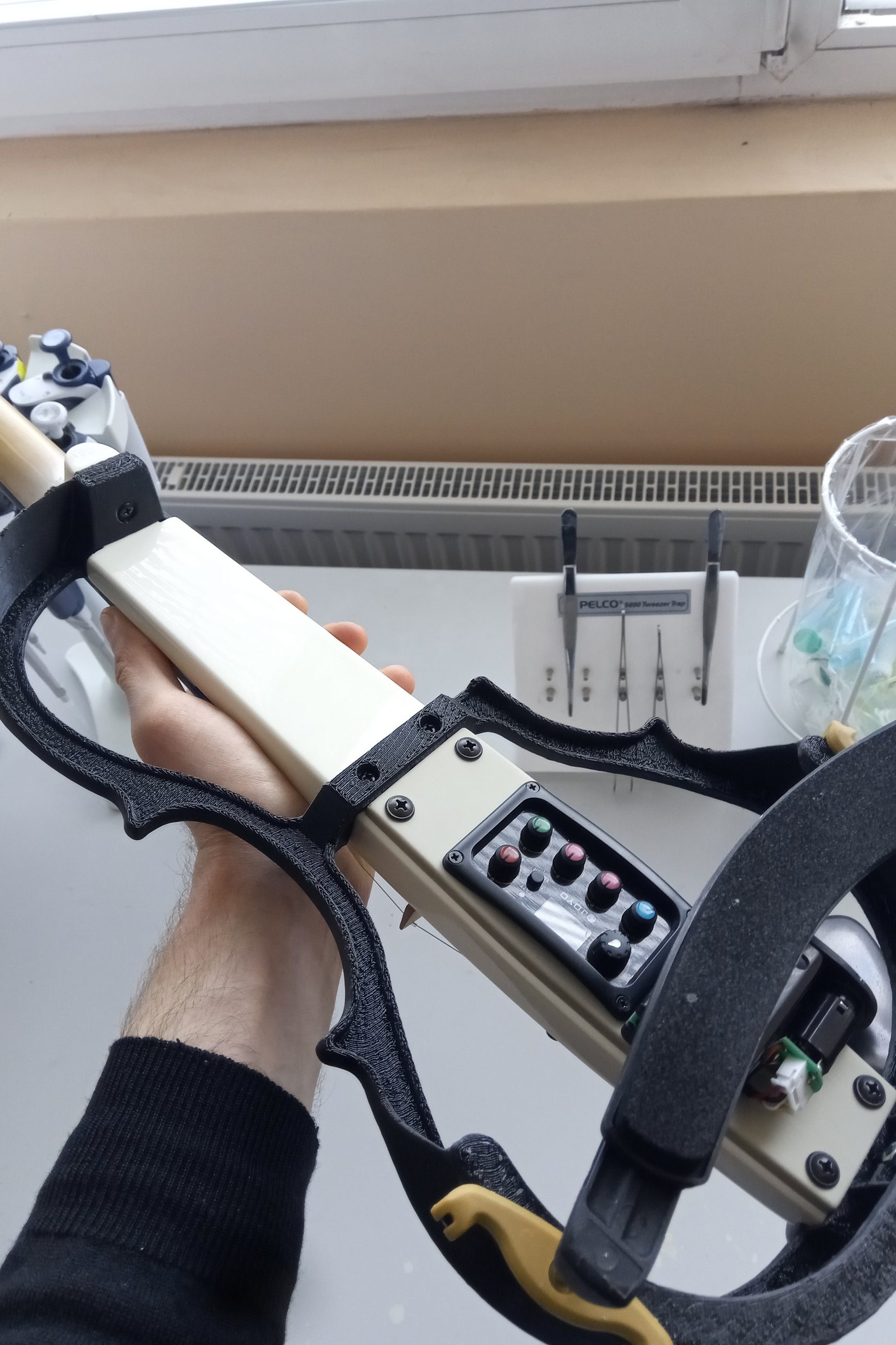

We received an order from a musician to restore the broken body of the electric violin. Due to the thin violin shapes, the original body cracked at the mounting place and eventually broke. As the technical part of the instrument remained intact, the client asked us to scan the broken violin frame, thicken weak areas, and print a new body. For this purpose, we used an Artec Space Spider 3D scanner with an accuracy of 0.05 mm and an FDM-based 3D printer with PETG material. This material is strong and easy to post-process, so it will allow the customer to perform the desired surface post-processing.

Restoring the violin body using 3D technology is a particularly quick way to restore a broken part that is not available on the market. This saves on repair costs and ensures sustainability by not disposing of items that can still be repaired. In addition, 3D technology allows you to improve your part design and create an even stronger and more durable product.

3D printing technology: FDM ( Fused Deposition Modeling)

3D printing material: PETG

Size (mm): 360 x 210 x 50 mm