If you drive a rare car and have ever had to repair it, you have probably noticed that some parts are particularly hard to find. We have customers who complain they can’t get it, don’t want to wait so long, or just want to save money. Glad we can help them in this place.

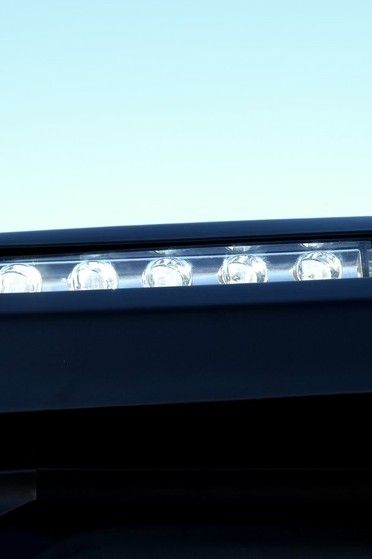

One of our projects is the restoration of the lamp trim on a rare Mercedes-Benz Brabus car. The customer provided us with a cover for one of the lamps a mirror copy of which we reproduced using 3D scanning, modeling and printing technologies. Based on the data from an Artec Space Spider 3D scanner, our designers created a parametric 3D model of the lamp cover. This eliminates deformed, damaged areas and ensures that the new part will be particularly smooth. The 3D modeled part was printed using an FDM technology-based 3D printer and environmental conditions-resistant PETG plastic.

This production method allowed the customer to get the needed part in just a few days and saved production costs. Using the computer 3D model, the customer will be able to print more parts at any time in the future.

3D printing technology: FDM (Fused Deposition Modeling)

3D printing material: PETG

Size (mm): 331.62 x 179.80 x 23.36