Worn parts can instantly make your life bitter. Especially if we are talking about vintage devices or vehicles. Rare, discontinued parts cause inconvenience and may make your wallet thin. In this case, 3D technologies will definitely help you!

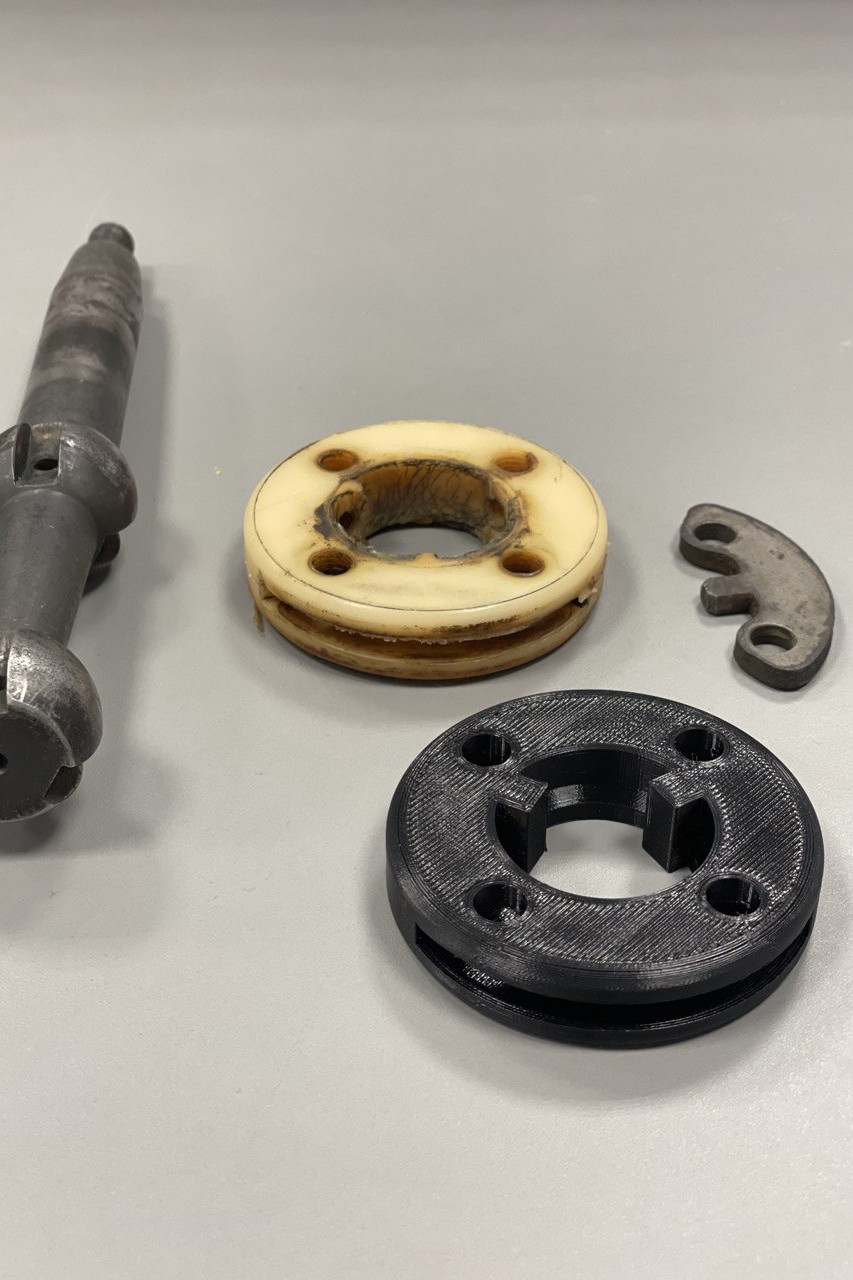

We received a request from the “Vilnius Public Transport” Company to restore a part of the gearbox mechanism of an old bus. This rubber part has lost its properties over many years of service, and it was impossible to purchase a new or used one. For this reason, we performed a precise restoration. A 3D model of this old part was created using computer modeling software. We printed it with an FDM machine using flexible 3D printing material TPU95-HF. The properties of this filament fully match the original, because the part had to be strong, to hold the elements of the assembly, but at the same time elastic to fit on the required part.

This production method was an extremely fast and cheap option to fully repair the bus and return it to the city streets in just a couple of working days. This saved the company from the high costs of replacing the entire gearbox or even the bus itself.

In the photos, the original part is yellowish and the new one is black.

3D printing technology: FDM (Fused Deposition Modeling)

3D printing material: TPU95-HF

Size (mm): 72.70 x 72.70 x 15.00