Engaging in 3D technology we often receive requests to produce one or another unique product. Whether it’s a single sculpture, an architectural design, or a scaled-down model of a unique vehicle. It would be particularly expensive and time-consuming to produce all of them using standard production methods. Thanks to 3D technology, we can implement such projects much faster and easier.

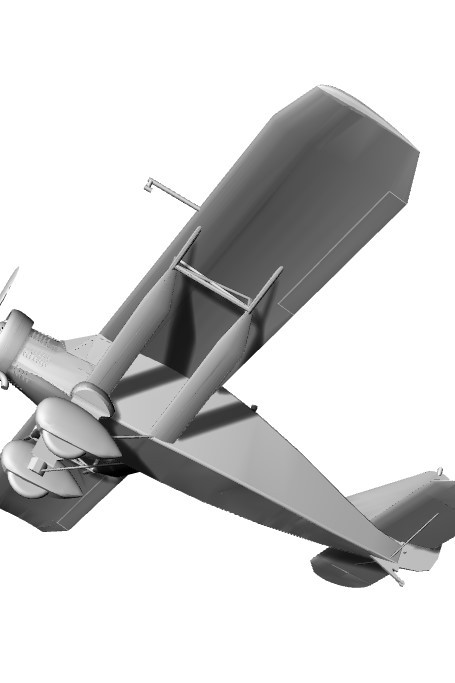

This time we would like to share the model creation project of the Lithuanians S. Darius and S. Girėnas airplane, named “Lituanica”. “Bellanca CH-300 Pacemaker” is the aircraft they flew across the Atlantic Ocean but crashed just a tenth of the way to Kaunas. Nevertheless, this historic event is still considered one of the greatest achievements in the history of aviation.

We created a 20 cm long copy of the “Lituanica” airplane. Based on historical photos and data, the airframe and inscriptions were restored with great precision and detail. The created 3D model was printed in parts, combining FDM and SLA printing technologies. SLA printing allowed the smallest parts of the aircraft to be produced with particular precision, while FDM technology was used to produce the largest parts of the fuselage. We did this with “Formlabs” and “Zortrax” 3D printers. The 3D printed fragments were glued, processed and painted in the colors provided by the customer. An airplane stand was also made separately.

3D technology has made it possible to quickly and accurately reproduce a 3D model of a famous airplane based on historical data. This plane will complement the collection of Lithuanian military aircraft models and will be used as a souvenir/gift for important persons or organizations.

3D printing technology: FDM (Fused Deposition Modeling), SLA (Stereolithography)

3D printing material: Z-Ultrat, Z-HIPS, Standard resin

Size (mm): 200.0 x 356.7 x 89.4