Almost all manufacturing companies often encounter a lack of one or another part in the production. Global unrest has shown that when supply is disrupted, companies suffer severe losses. Nevertheless, we are glad that more and more companies are discovering the advantages of 3D technologies and thus solving the problems that have arisen.

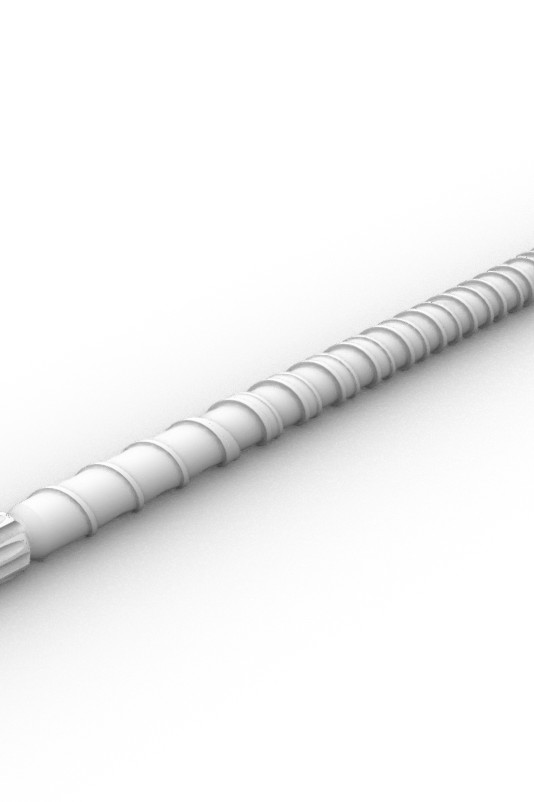

One such project is the restoration of production drawings of industrial machine extrusion screw. Particularly advanced metrological 3D scanner „Kreon“ was used to complete this order. Thanks to this unique scanner and robotic arm combination, >5 meters long object was scanned with an accuracy of up to 9 microns. An extremely high-precision 3D model allowed us to reproduce the parametric shapes of complex surfaces with very high accuracy. The resulting STEP model was additionally converted into 2D drawings requested by the manufacturers.

This solution is a quick and convenient way for the customer to prepare production drawings. Having the drawings allows the client to order the production of the extrusion screw at any company and at any time when needed. This allows you to be independent of suppliers and to carry out your company’s activities efficiently. However, there are more advantages. Having production drawings, you can easily make the necessary corrections and improvements at any time. And of course – be calm so that when the machine part wears out, you won’t experience the headache of finding hard-to-find parts for your equipment again.

Size (mm): more than 5 meters in length