Let’s imagine the situation. A huge manufacturing company working 24 hours per day. Large and expensive machines produce millions of products. Every hour and minute is planned. Tens or even hundreds of customers are waiting for their orders to be delivered on time. But suddenly, the machine breaks down. Due to the broken part, processes cannot continue. There is no analog in the market, you need to buy the whole set and the shipping can last even a few weeks. Real situation? Really so. Unfortunately, this means huge losses to the company.

In this way, we received an urgent order from Pakmark – one of the largest and most modern packaging and labeling solutions companies in Lithuania. Their need was particularly urgent to scan and print the parts of the printing machine’s paint peristaltic pump. Without these parts, the pump cannot function as a result of which the ink supply to the press machine is not appropriate and the work cannot be carried out.

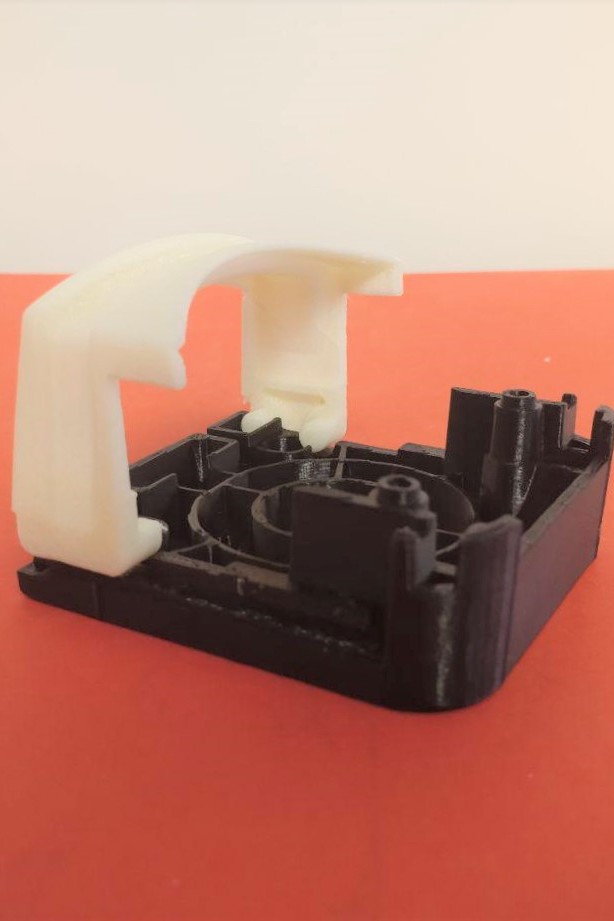

We responded fastly and, on the same day 3D scanned and on the second day morning pro- vided 3D printed parts to the client. 3D scanning services were performed with the ultra-fast and accurate “Artec Space Spider” 3D scanner. This 3D scanner is capable of scanning with 50 μm accuracy and ensures an extremely high quality of scanned files. 3D printing of scanned models was done by the “Zortrax M200” – 3D printer of FDM technology. This 3D printer has won several awards and is recognized as one of the best desktop-class printers on the market. The printing was done using a robust and load-resistant “Z-Ultrat filament. The printed parts have completely replaced the broken parts, allowing the customer to restore the production very quickly.

Restoration of original parts is a fast-growing area for 3D printing. According to the customer, it is not possible to purchase these parts in the market. Suppliers offer to buy only a new set, but the price is as high as 4000 eur. In addition, it is necessary to evaluate not only the costs but also the delivery time that stop production for longer. That’s why the client contacted us. In just 1,5 business days, the client had two sets of these parts. With 3D models, they will be able to apply for these parts at any time in the future.

In this case, 3D printing has not only saved up to 40 times the cost of repairing works but also reduced downtime to 1.5 days!

3D printing technology: Fused Deposition Modeling

3D printing material: Z-Ultrat

Size(mm): 77x33x51;31x83x76