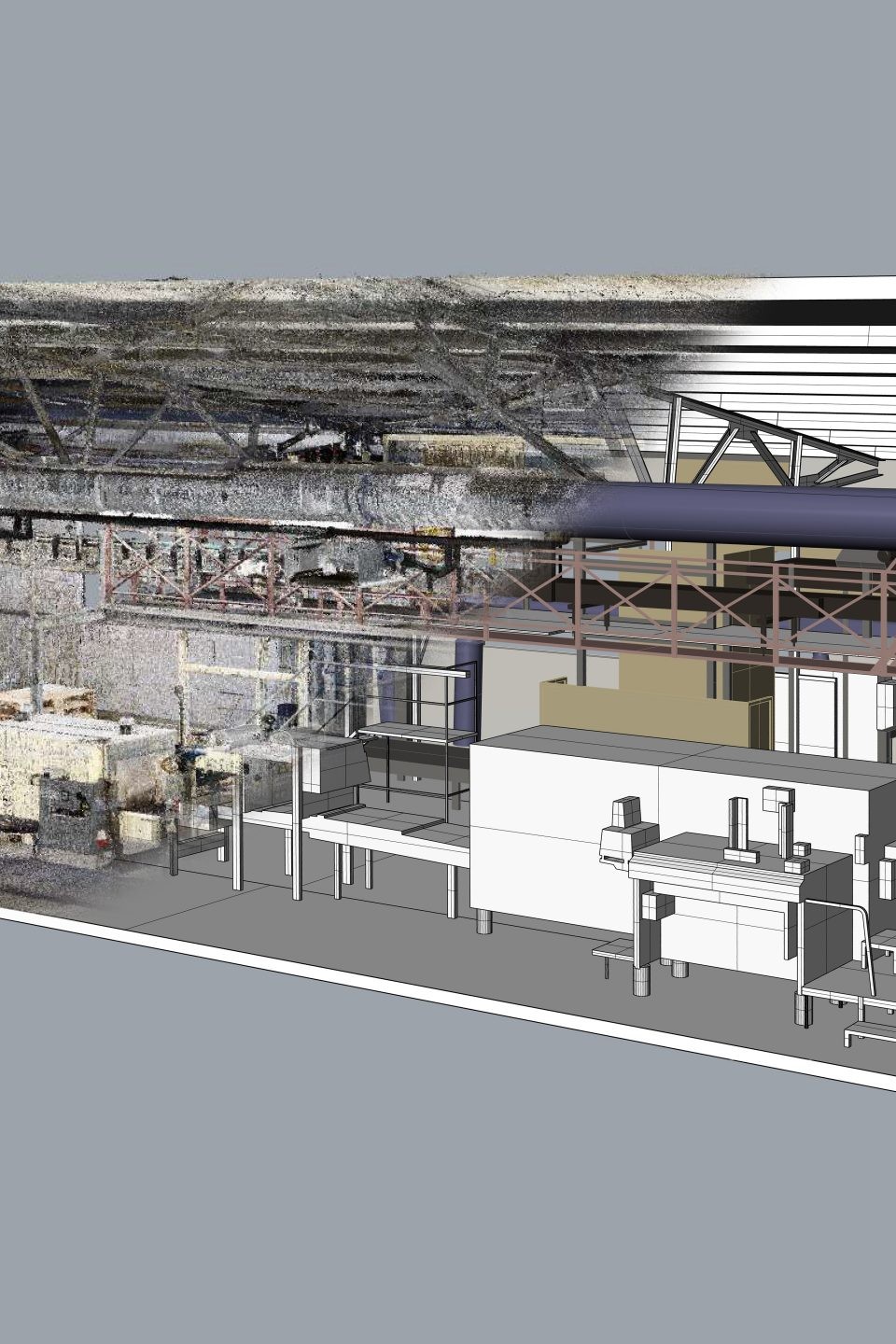

3D scanning is an up-and-coming way to perform quick and high-quality measurements. Because of this technology you can save a lot of your time, reach the highest level of precision and avoid accidental human measurement errors. 3D scanning of large spaces is already becoming usual for accurate measurements, making simulations of changes in the layout of premises, and preparing visualizations as well.

This time we are sharing the project of industrial premises 3D scanning. According to the client’s needs, we performed the highest accuracy digitization by using especially advanced 3D scanner “Faro S150”. In order to reach the highest accuracy, 3D scanning was being performed at one hundred points at various locations in the factory. It allowed us to generate the result with +/- 2 mm tolerance. Thanks to fast and advanced equipment 3D scanning can be performed only in one working day.

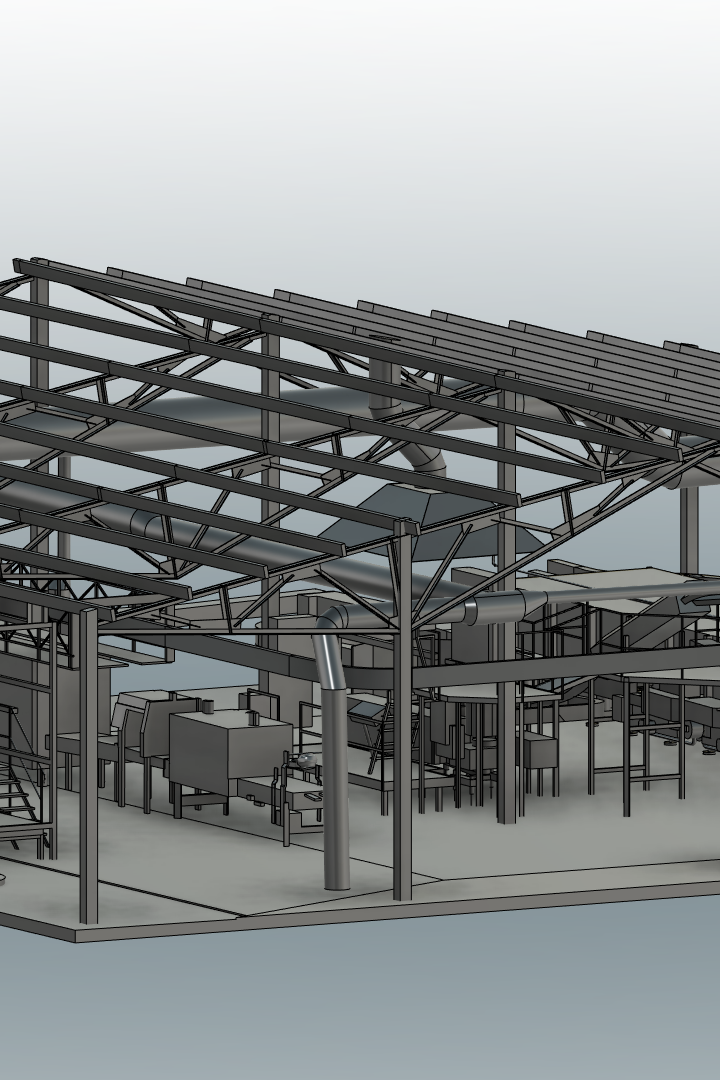

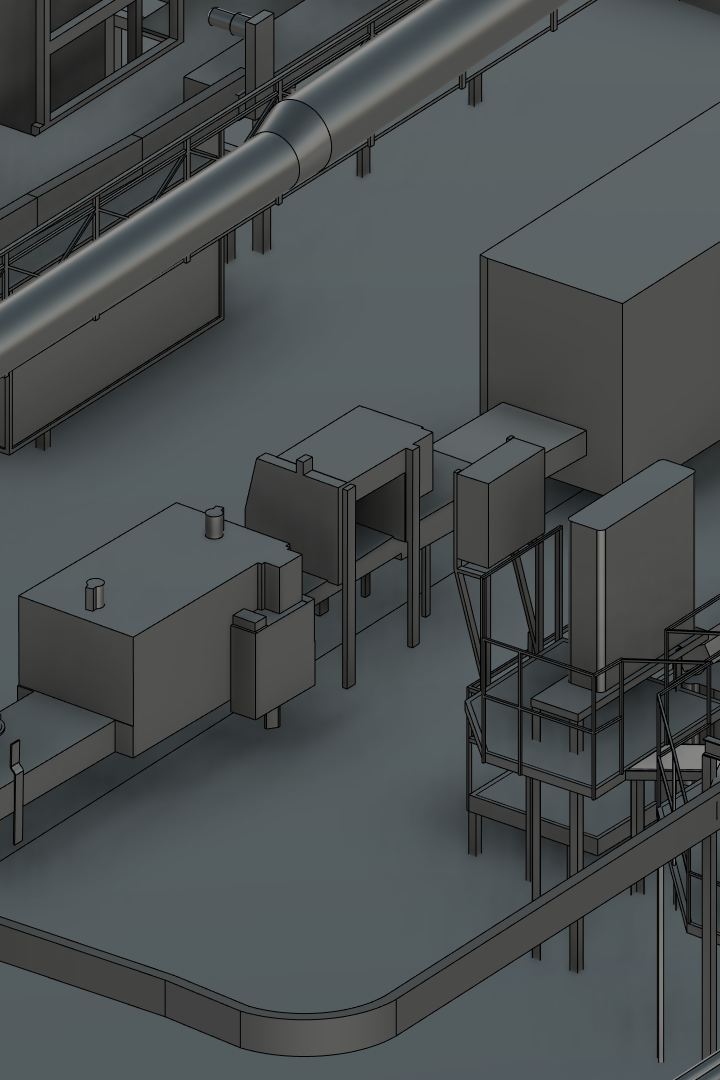

According to the client’s request, 3D scanned data was converted to STEP file (in LOD 200 level of development). The CAD model was used to evaluate the installation possibilities of new production equipment and to prepare an installation plan. This 3D model format is especially useful for any kind of measurement, model transformation, improvement, or documentation purposes.

Size (m): 24.430 x 23.440 x 7.448