In the production industry, every minute counts, and any failure can result in costly downtime. This is one of the main reasons why 3D printing is beneficial in this area.

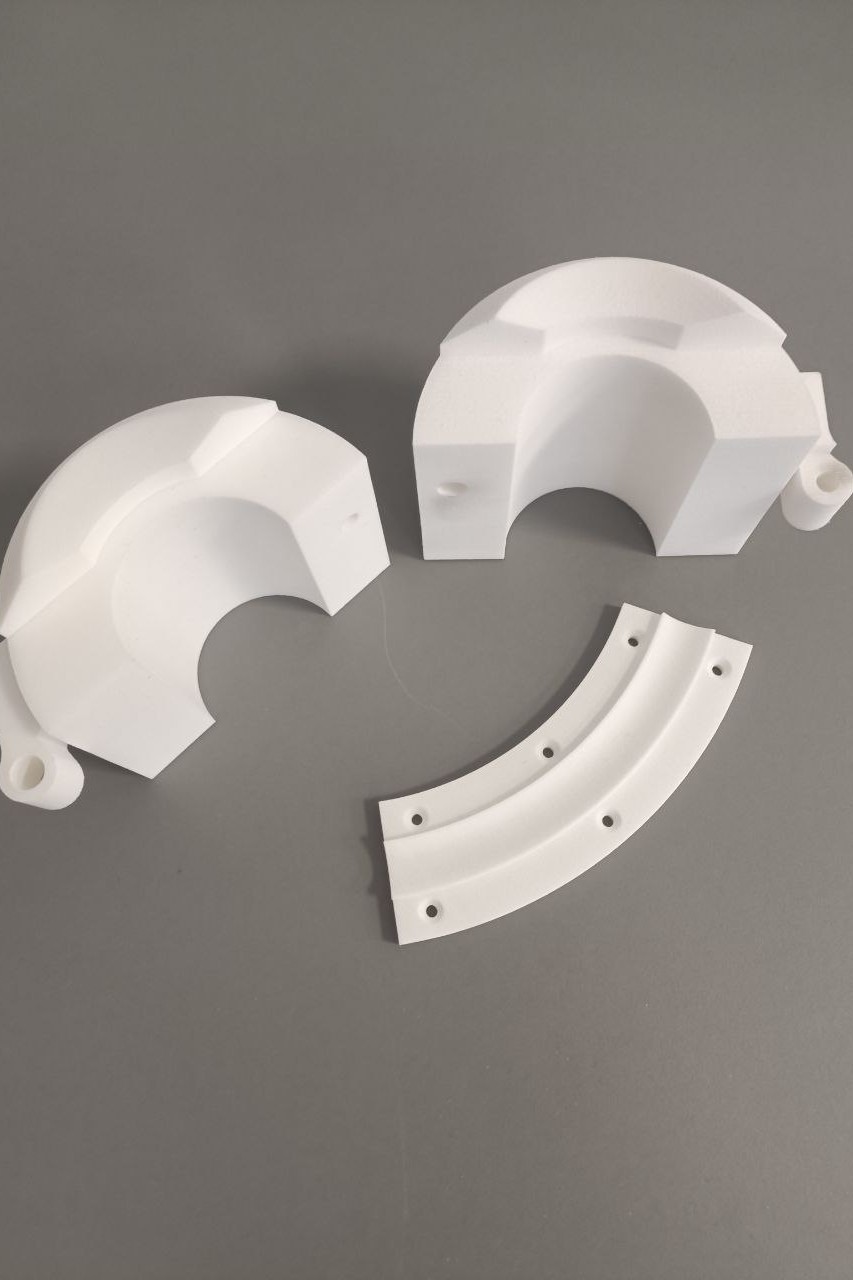

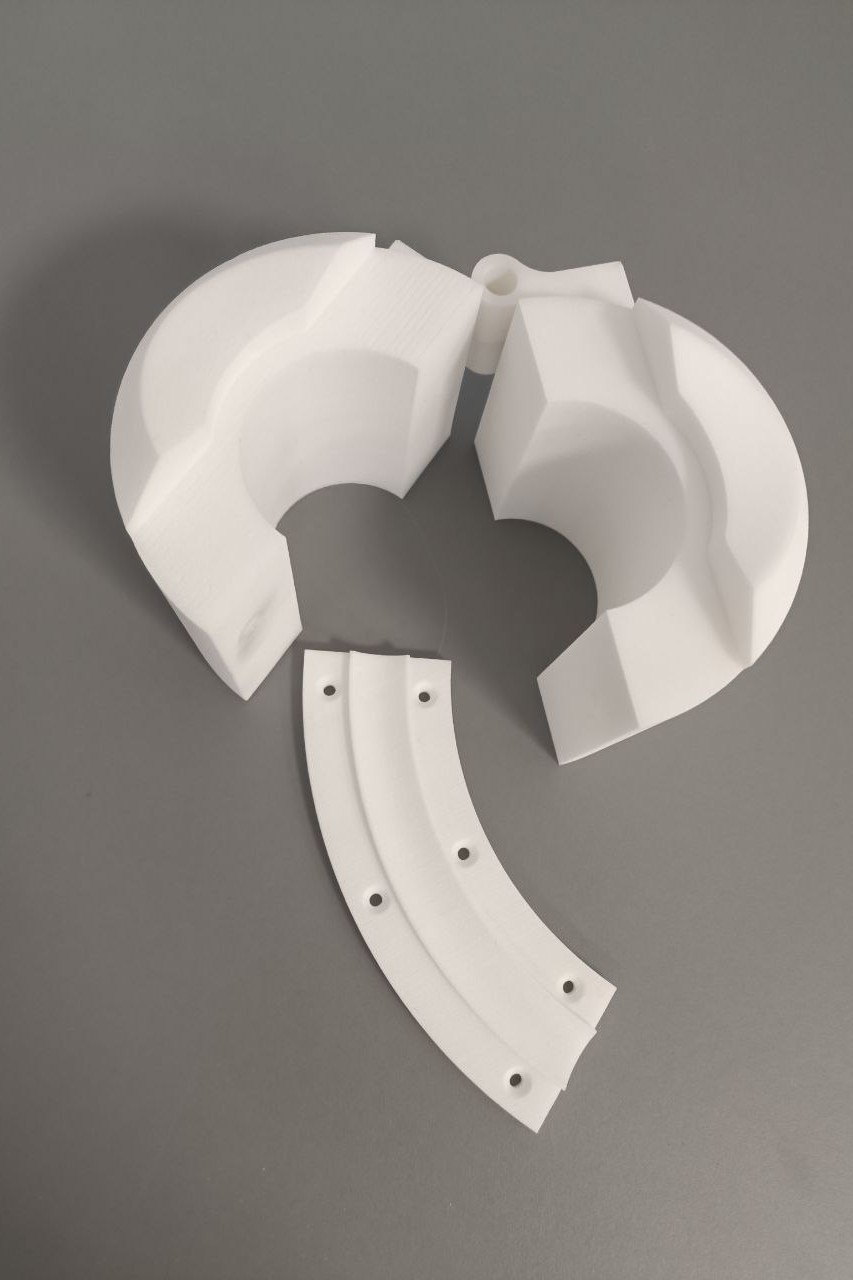

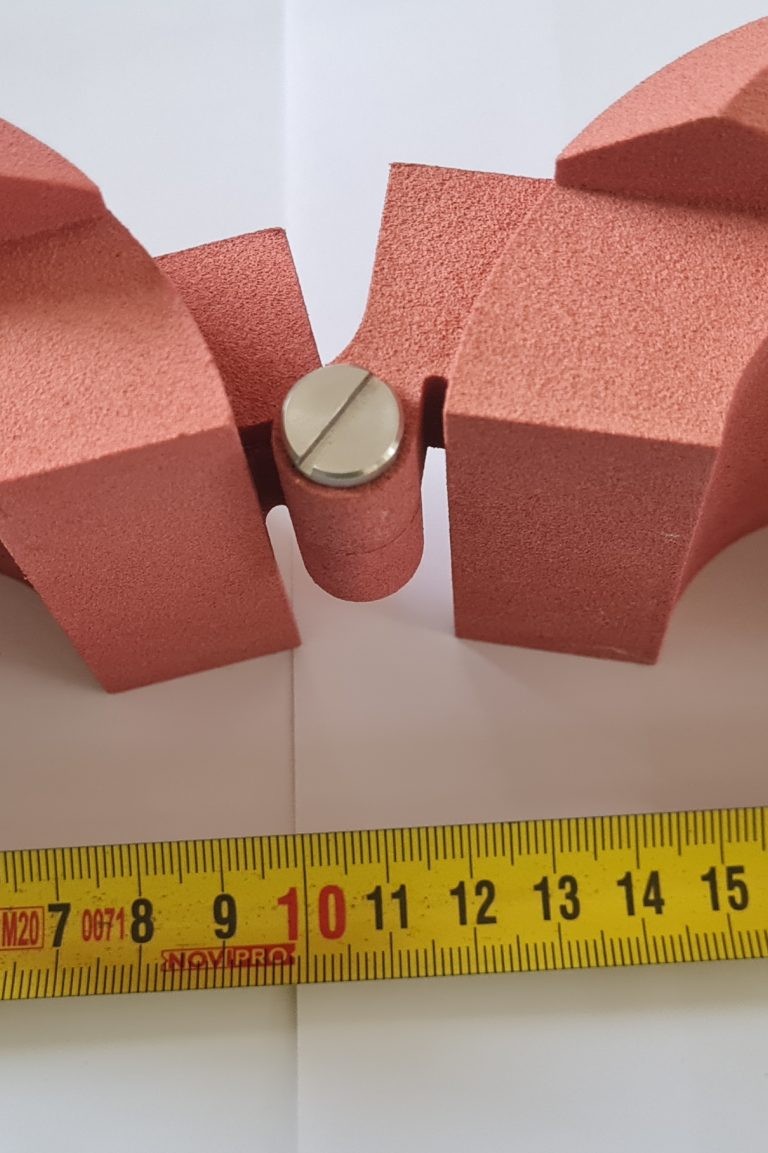

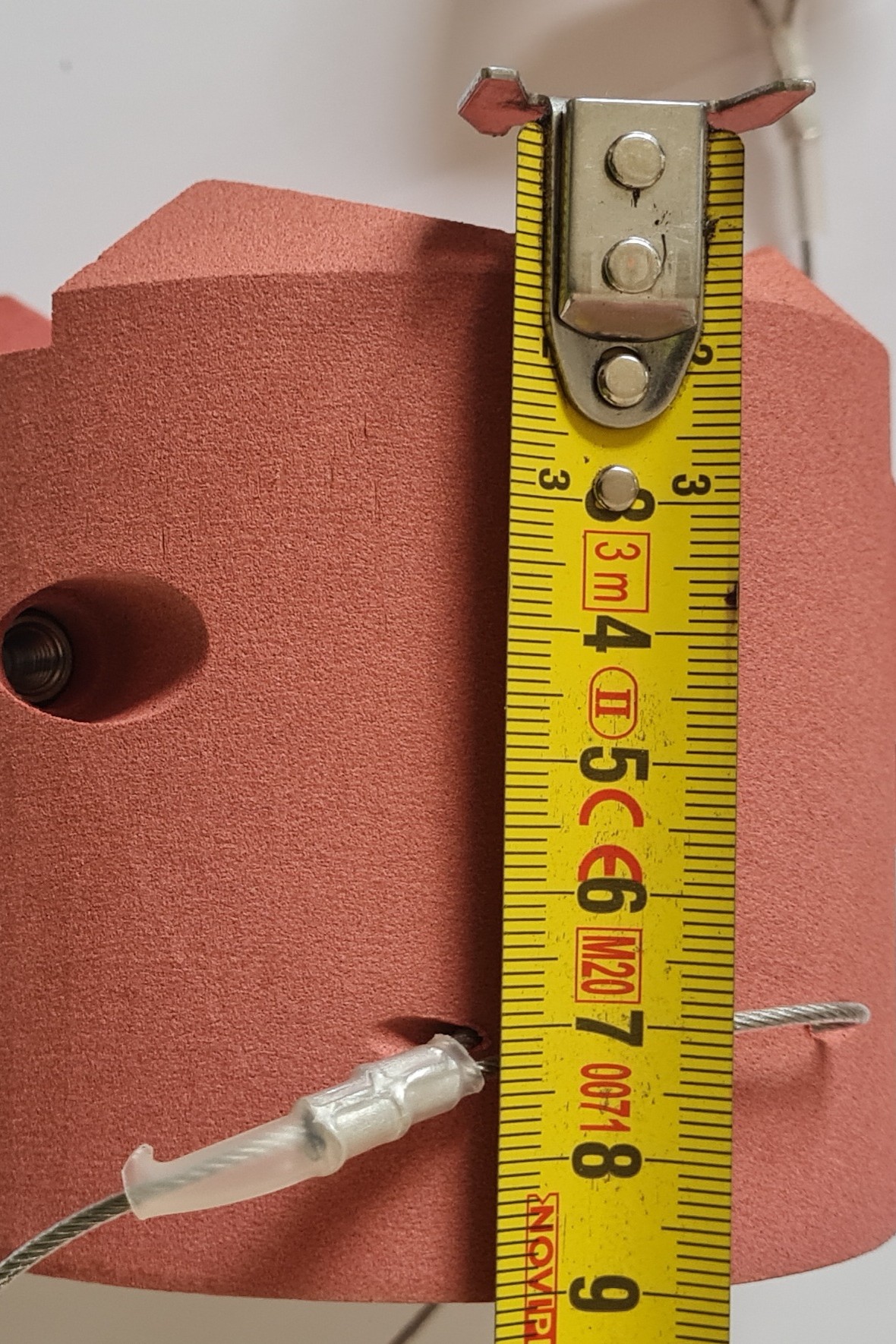

A manufacturer of heating and equipment approached us with a request to restore parts of a hydraulic unit. To that end, we performed a detailed 3D scan using the ultra-precise “Artec Space Spider” 3D scanner, which is capable of scanning objects with an accuracy of up to 0.05 mm. We then prepared the scanned models for printing and printed them using the SLS technology machine, specifically the “Prodways Pro Maker P1000” industrial 3D printer and PA11 material. These parts are extremely strong, durable, and fully meet the customer’s needs.

This rapid method of repair is efficient for broken or worn equipment, with 3D modeling and 3D printing often taking just one to several days. Furthermore, having 3D models allows for even more time savings in the future since there is no need to repeat the scanning process to print those parts again.

3D printing technology: SLS (Selective Laser Sintering)

3D printing material: PA11

Size (mm): Ø 100 mm