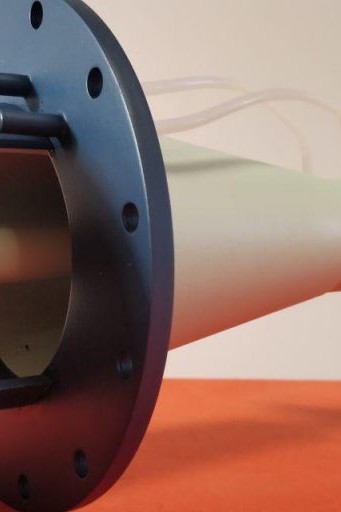

Finnish company which specializes in the manufacture of special pumps and industrial mixers ordered a single device 3D mockup which was created using 3D printing technologies and was made from more than ten 3D printed elements.

3D model provided by the customer has been optimized and adapted to 3D printing technology. The final model was simplified, extremely small elements were removed or made thicker.

Parts were made with “Zortrax M200” 3D printers and Z-ULTRAT plastic to print product items for its robustness and handling ability.

The printed models were further processed by various means and painted in the necessary colors according to the wishes of the client. The duration of the project is just four weeks, including shipping. This shows that 3D modeling and mockups 3D printing are ideal for creating such layouts.

3D printing material: Z-ULTRAT plastic

3D Printing Technology: Fused (FDM) (fused deposition modeling)

Product size (mm): 520 x 75 x 75