In the face of the world’s threatening COVID-19 virus, contact avoidance and special hygiene are the first weapons in this fight. 3D printing also makes a significant contribution here. Some use 3D printers to manufacture safety shields and lung ventilator valves, while others develop and implement products to reduce contact with potentially hazardous surfaces. Taking care of medical safety, we have created and improved a 3D model of face shields, which is now freely accessible to anyone. And this time we share a small series production order of Philip Morris door handle accessories.

At the customer’s request, were printed 164 sets of door handle accessories. These acces- sories are attached to the handle so that a person can open and close the door using a bent hand without directly touching the handle. The aim of this is to reduce the spread of the virus. We are happy that our customers protect and take care of their employees by providing them with such a measures.

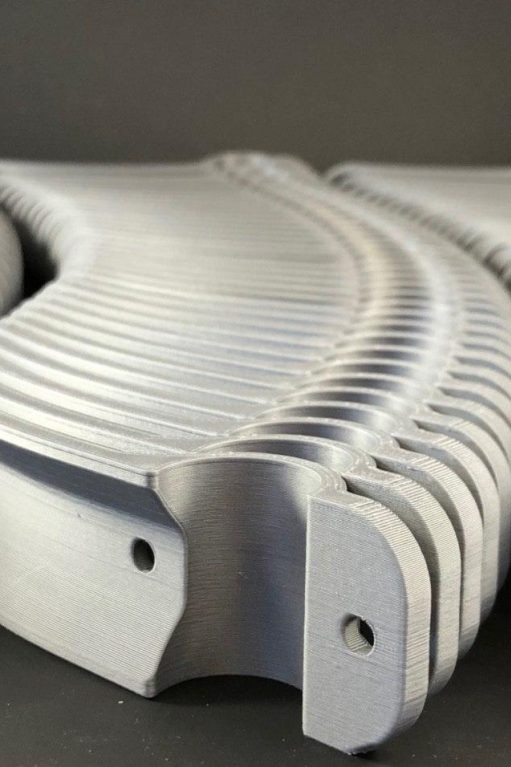

To fulfill the order, we used extremely accurate and fast Zortrax M200 printers, as well as gray ABS plastic. This durable material and high-density infill ensure that the handle accessories can withstand the loads assigned to it and are be long-lasting. The set consists of two parts, which are fastened with bolts and nuts.

This order once again shows that 3D printing is a particularly fast and affordable solution when you need to get particularly new and personalized products here and now. Hopefully, these solutions will help curb the spread of the virus, and life will return to old tracks. Be safe and protect yourself and your employees!

3D printing technology: FDM (Fused Deposition Modeling)

3D printing material: ABS