Many individualization solutions are often encountered when installing new production facilities. Large equipment or units are usually installed directly in the production premises, so the builder is left with the most important issue – how to adapt the new equipment to safe and comfortable work. 3D technology is particularly helpful in this regard.

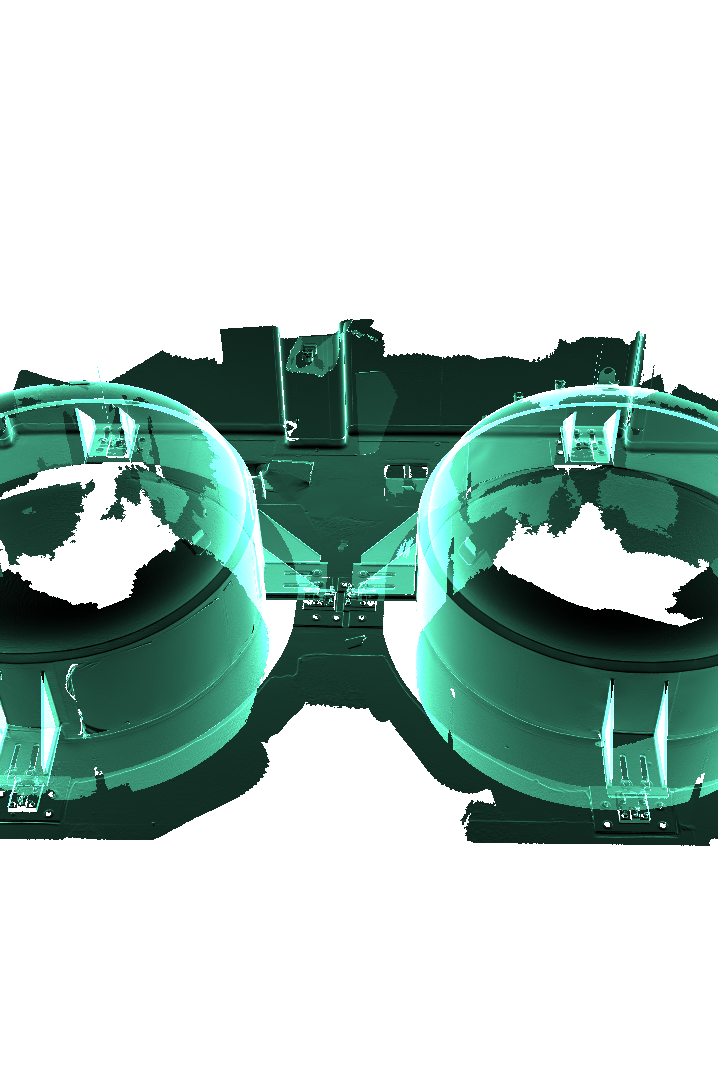

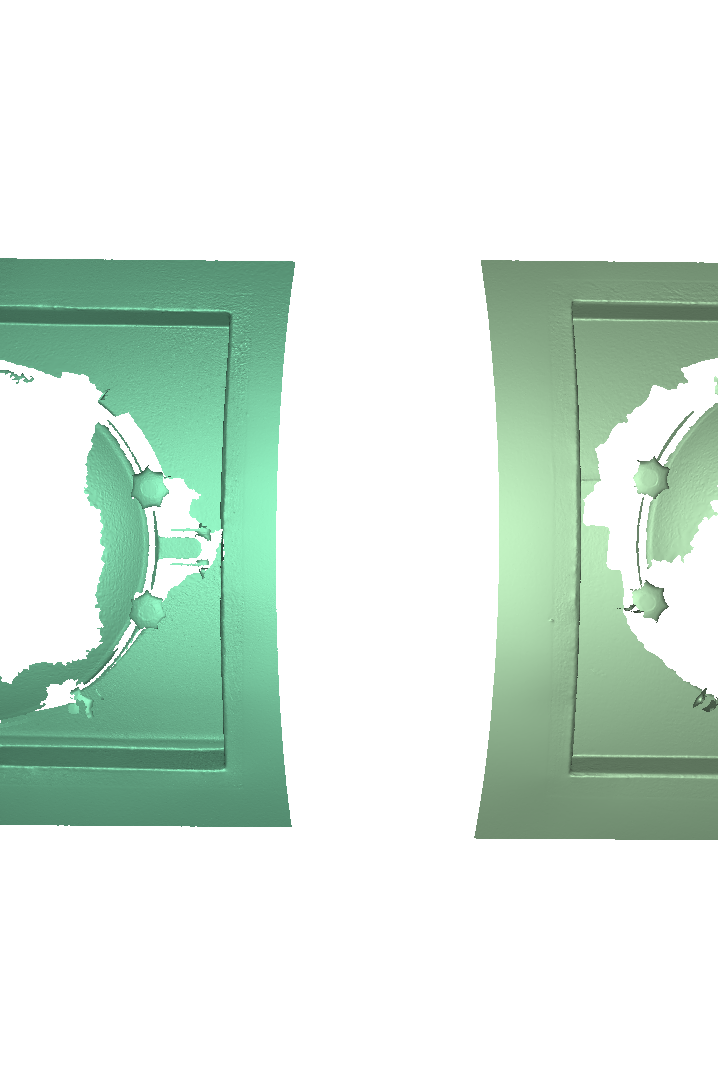

This time, a customer installing a new production unit asked us to perform a 3D scan of the required construction sites for 2.5 m diameter tanks. We used the most advanced and fastest “Artec Leo” 3D scanner for this process. This 3D scanner captures environmental objects with an accuracy of up to 0.1 mm. High scanning speed ensures comfortable work. A 3D scan of the four tanks was done in just an hour.

The 3D scanned models were used to make protective skirts covering holes in the floor and frames around the doors. All welding work was done directly in the factory and it is known

that the welds are not perfectly cylindrical, so the 3D scanned data allowed for particularly accurate modeling and fabrication of the protective parts. Despite the non-ideal geometry, the protective parts were made to fit snugly and cover the required openings.

This method of measurement particularly simplifies the production process and ensures that all dimensions are collected not only quickly but also accurately.

Size (mm): Ø 2500.00