Car is a sophisticated, consistent system. Each element of it is very important and responsible for the operation of other elements, assemblies, and mechanisms. Accuracy in such a system is paramount. Especially when it comes to sports cars.

The most common problems arise when there is a need to accurately measure the geometry of complex parts. Manual measurement is very time-consuming. Also, it is possible to make mistakes, inaccurate measurements later also entail significant financial costs when it comes to repeating the process and finding where the mistake was. However, 3D scanning can solve all of these problems.

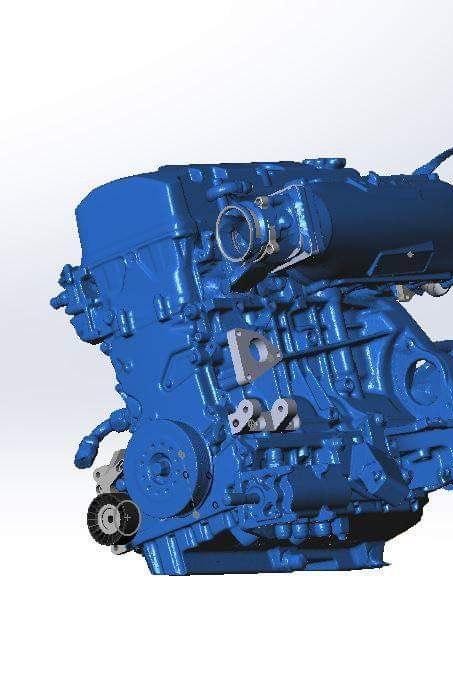

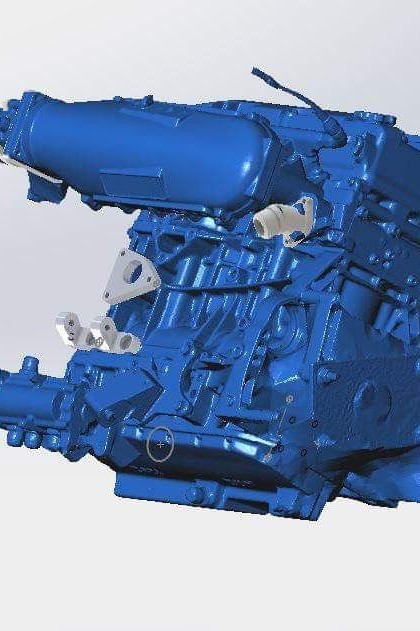

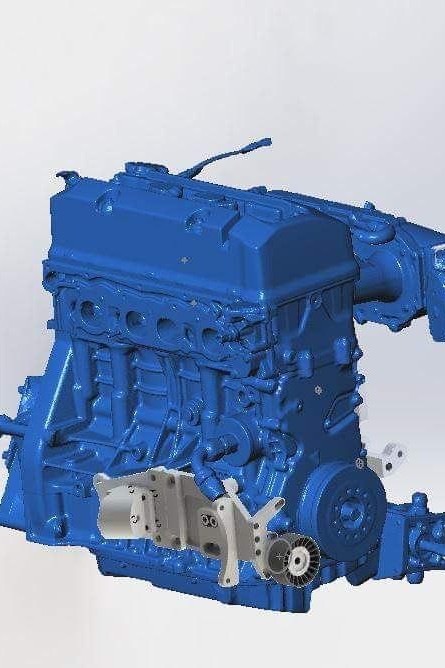

We were approached by a racing company with the need to scan the car’s engine. The geometry of the engine is extremely complex and manual measurements would be very difficult to make. For this reason, there was used 3D scanning. We performed 3D scanning with an “Artec Leo” 3D scanner capable of scanning up to 0.1 mm accuracy. The process took only a few minutes.

3D scanned data was used to create a customized, motor-mounted adapter and other parts. 3D scanning, in particular, accelerated the process and reduced the likelihood of possible errors. This type of measurement is extremely fast and reliable.

Scanned object size (mm): 567.30 x 672.22 x 620.25