Small-scale production with 3D printing technology is rapidly gaining popularity! After experiencing its benefits, our customers are increasingly ordering 3D printing of the products they need in small batches. In this way, they can offer the market a wide range of products that are carefully adapted to the needs of demanding customers, but at the same time maintain an optimal price.

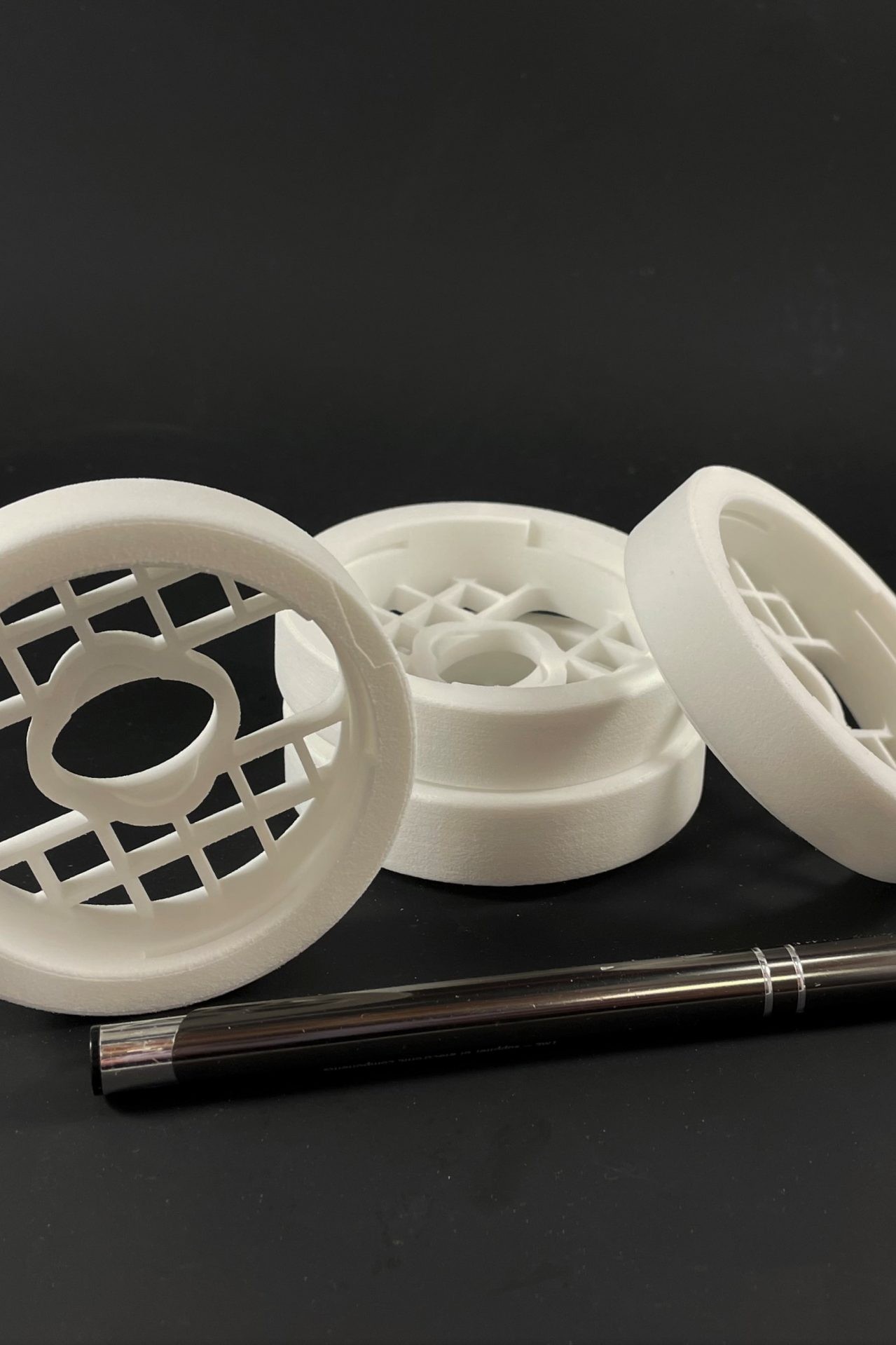

Today we are sharing another successfully and promptly implemented small-scale production project. It is the production of 500 pieces of caps. These covers cover the air vents of mobile autonomous heaters. This is a powerful, especially lightweight heater developed by Tukada to heat the car’s interior and outdoor tent. For the 3D printing of these heater components, we have selected fast and reliable SLS printing technology. The Prodways ProMaker P1000 industrial 3D printer let us realize this project extremely fastly. Also, the PA12 material ensured exceptional quality and durability of the 3D-printed parts.

This method of manufacturing optimizes the production of small series products time, maintains the optimal production price, and ensures the longevity of the products.

3D printing technology: SLS (Selective Laser Sintering)

3D printing material: PA12

Size (mm): 75.00 x 75.00 x 18.00