3D technology is an extremely fast and convenient way to restore worn-out equipment. We often encounter situations where complex equipment is worn out and spare parts are very expensive and difficult to get on the market. Glad that 3D technology has already solved this problem, so our customers can forget about these inconveniences.

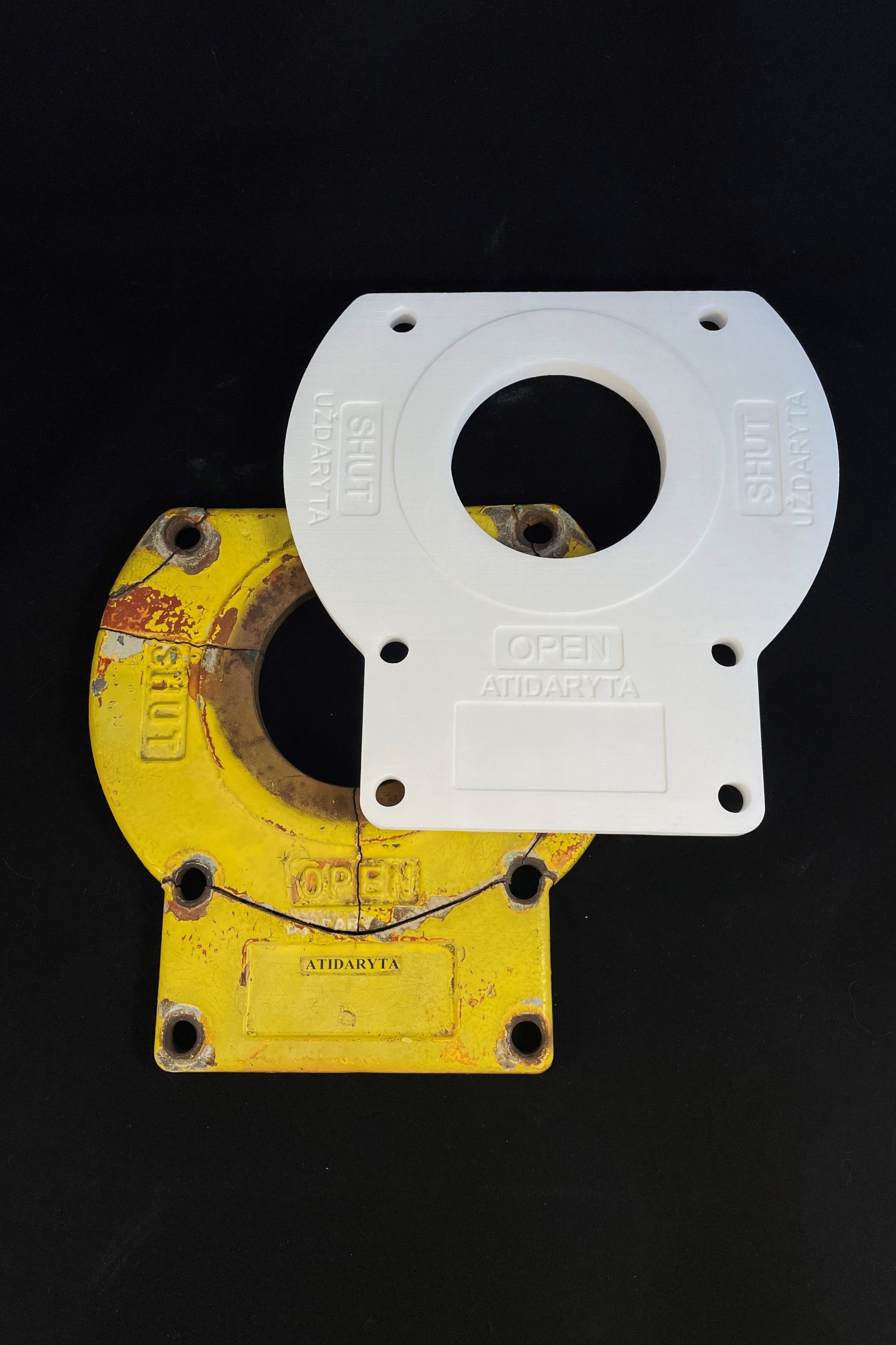

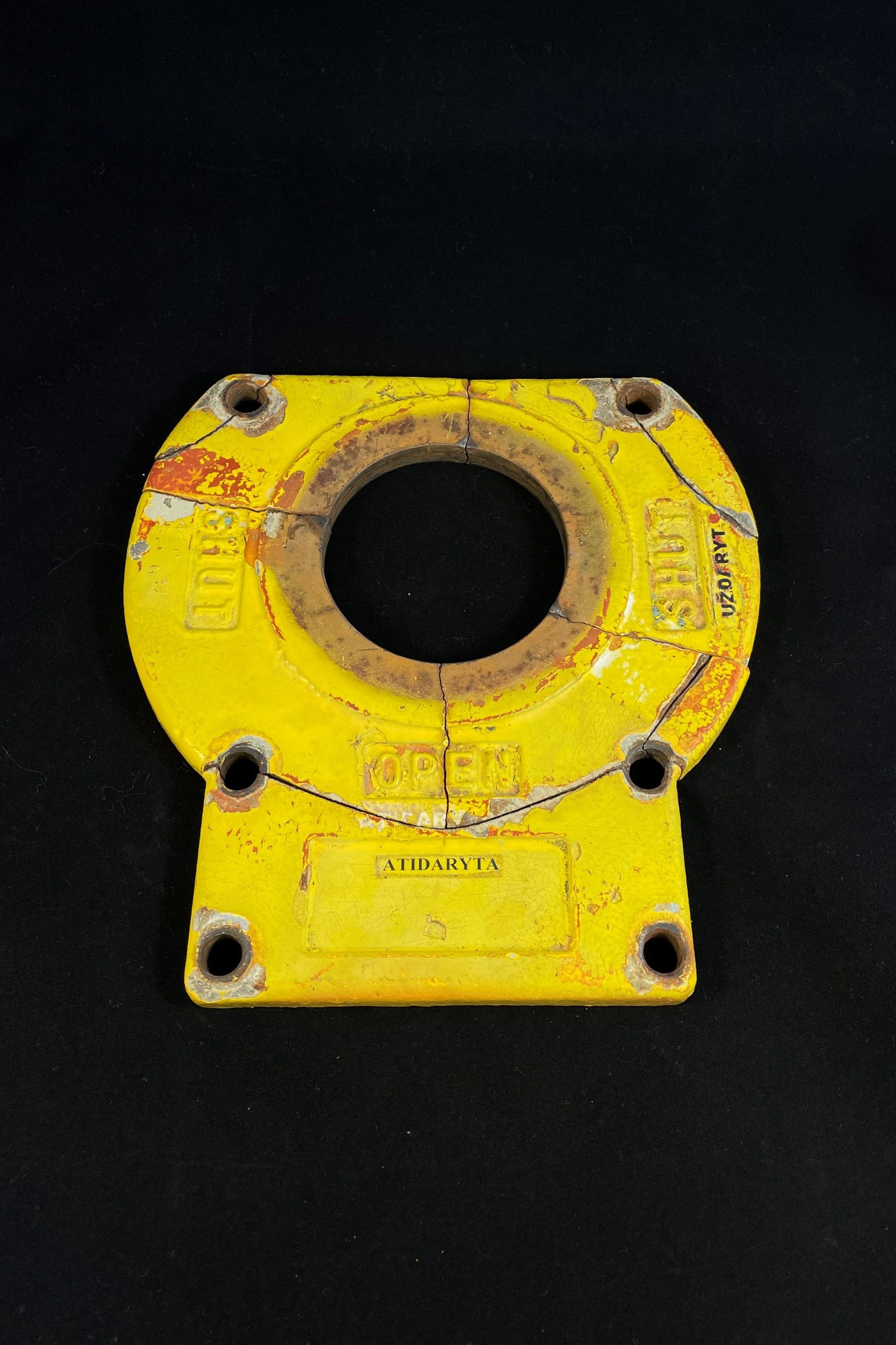

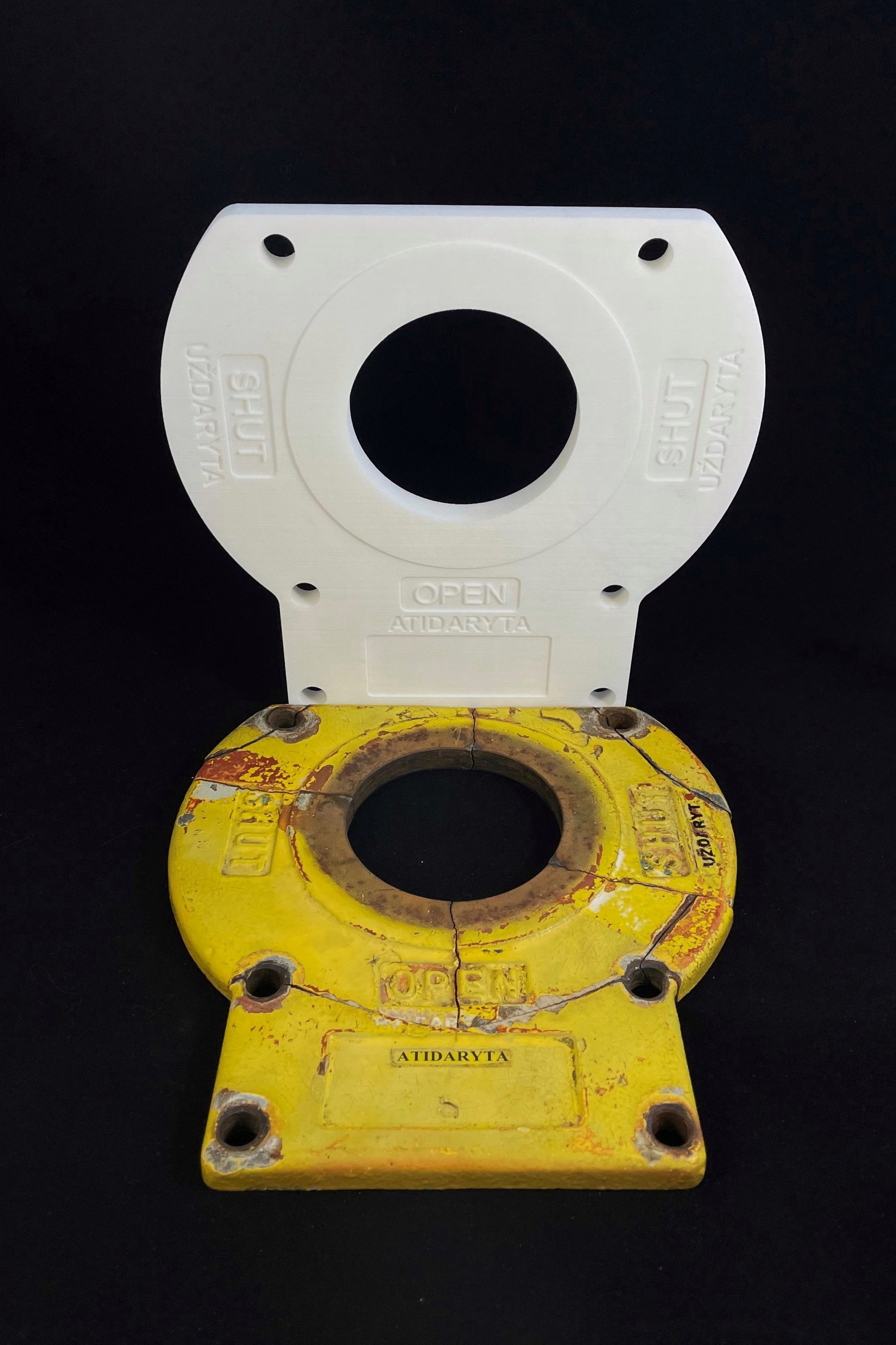

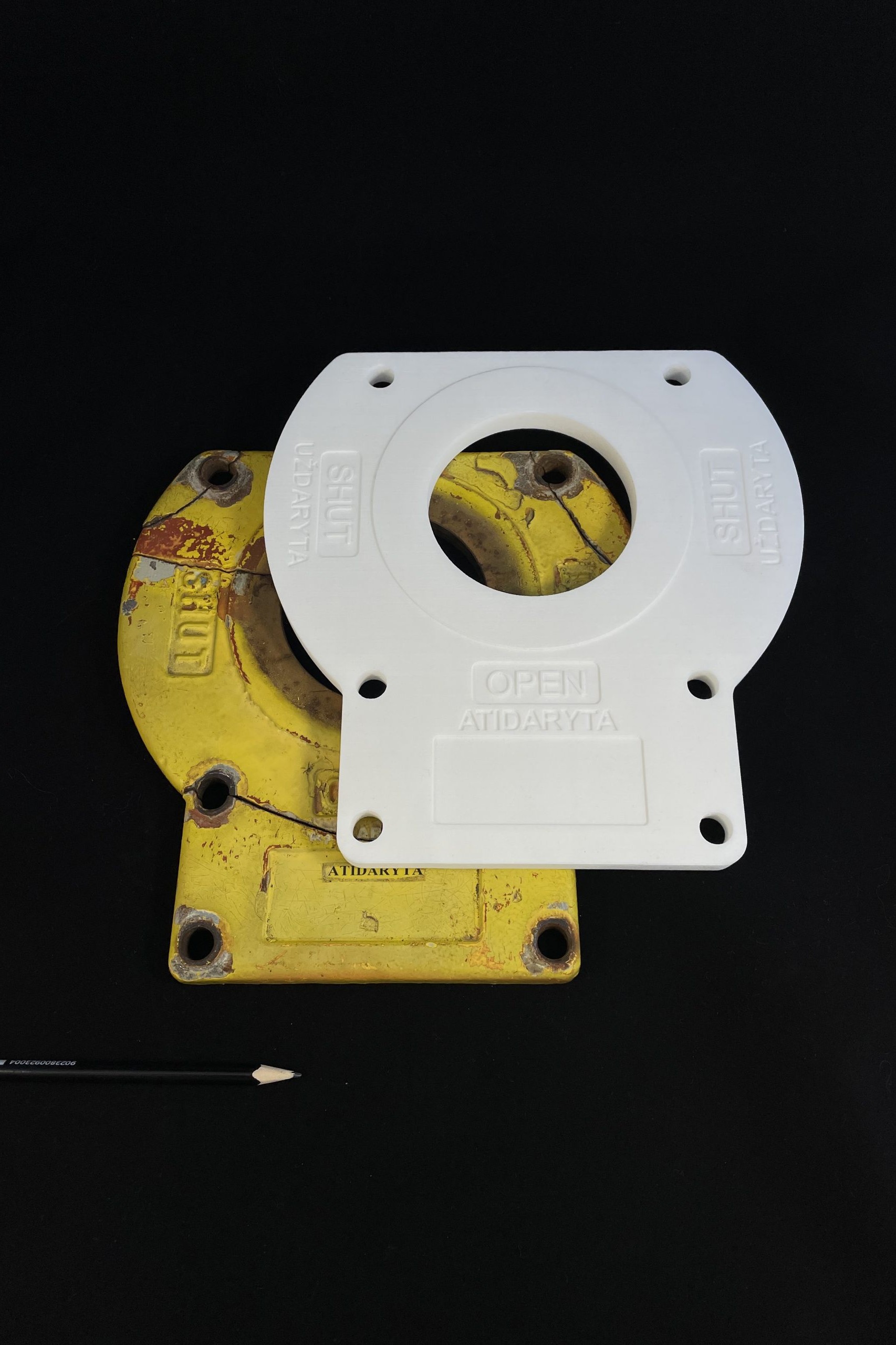

Another example of this is a restoration of the position indicator plate for the pipeline shut-off device. At the customer’s request, we restored the broken indicator plate and 3D printed a new copy of it. Based on the broken part provided by the customer, our designer recreated the fully parametric 3D model of the part, which we printed with the industrial SLS technology 3D printer “Prodways ProMaker P1000”. We used PA11 material, which is durable, resistant to loads and environmental influences.

The 3D printed part was installed next to the shut-off valve of the pipeline and is used in outdoor conditions. The 3D printed plate has fully replaced the worn-out original one and matches the end-use product requirements. This production method saves customers’ production costs and valuable time as well.

3D printing technology: Selective Laser Sintering

3D printing material: PA11

Size (mm): 225.50 x 223.00 x 13.00