3D printing is a well-known technology used in the automotive industry. It is now expanding to other large industries, such as shipbuilding, where it serves to not only digitize ships and their parts, but also to produce spare or custom parts.

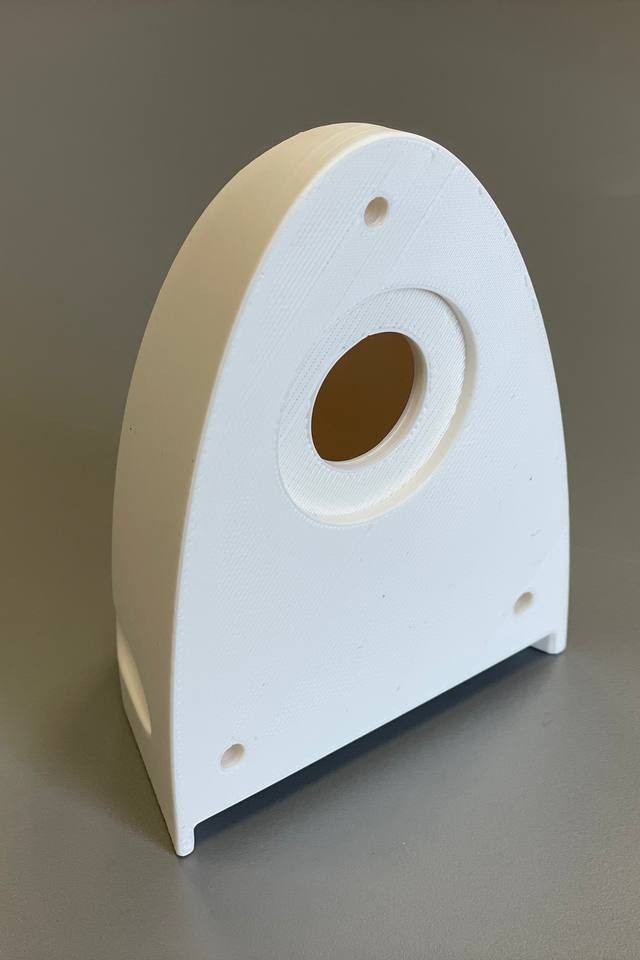

We recently received a request from a ship manufacturer to produce end-use ship light housings. To accomplish this, we used ASA filament, a material that is resistant to marine climate, along with advanced “Zortrax M300 Plus” 3D printers. This combination resulted in a fast production process and high-quality 3D-printed products. Once installed on the outer part of the ship, the printed light housings fully corresponded to the functions of the end-use product.

This production method enabled us to quickly produce approximately 70 ship light housings. The selected 3D printing plastic is durable and suitable for the ship’s operation, ensuring its longevity.

3D printing technology: FDM (Fused Deposition Modeling)

3D printing material: ASA

Size (mm): 74.45 x 50.00 x 100.00