Many modern manufacturing companies strive to work as efficiently as they can. However, none of us are protected against breakdowns, wear of parts and forced downtime. Sometimes this can be foreseen, and sometimes, unfortunately, not. In such cases, the supply of spare parts can be a particularly expensive and time-consuming process. However, don’t forget the cases when no one in the market producing it anymore. At this point, the situation can be saved by 3D technologies.

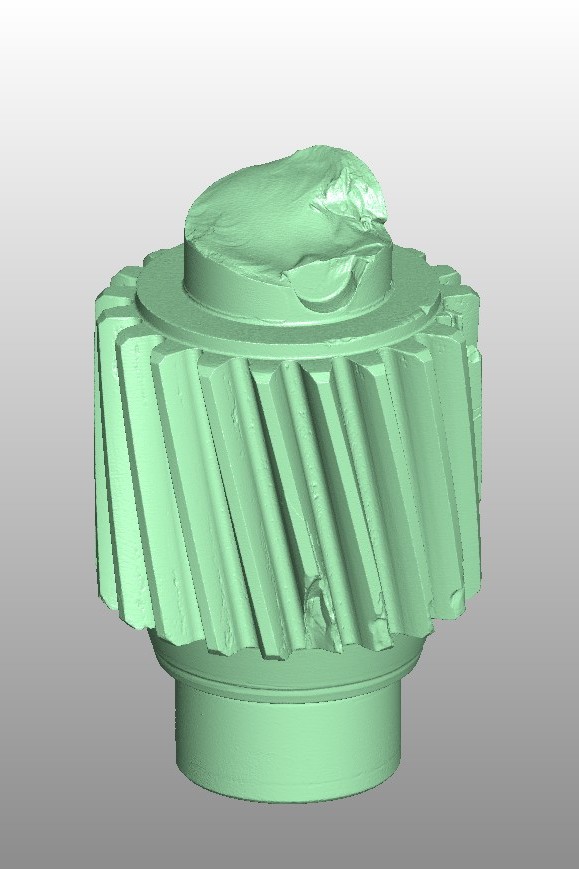

This is exactly what one of the companies engaged in recycling and extrusion engineering did. At their request, we performed a 3D scanning of the required part and model reconstruction to STEP format. It was done with the help of reverse engineering. For 3D scanning we used the high-precision “Artec Space Spider” 3D scanner. The scanned objects were captured with an accuracy of 0.05 mm.

The reconstruction of the scanned model to STEP format was performed by using world- renowned engineering software. The created high-precision STEP files are perfect for production – milling, cutting, 3D printing, or other popular production methods. In addition, the STEP file is readable by most CAD software, so you can make the necessary changes, enhancements, and modifications.

We are glad that this customer has already entrusted us with more than a dozen most important details. The prepared drawings of which are excellent not only for the production of new shafts and other machine parts but also for their improvement processes.

Size (mm): various, up to 1500 mm in length