It’s not a secret that 3D printing is an indispensable helper in reproducing original details. We have restored plenty of parts from a wide variety of fields. This summer, we added another area to our list – surfing! Have you ever wondered that 3D printing can be related to surfing? We are already convinced of that.

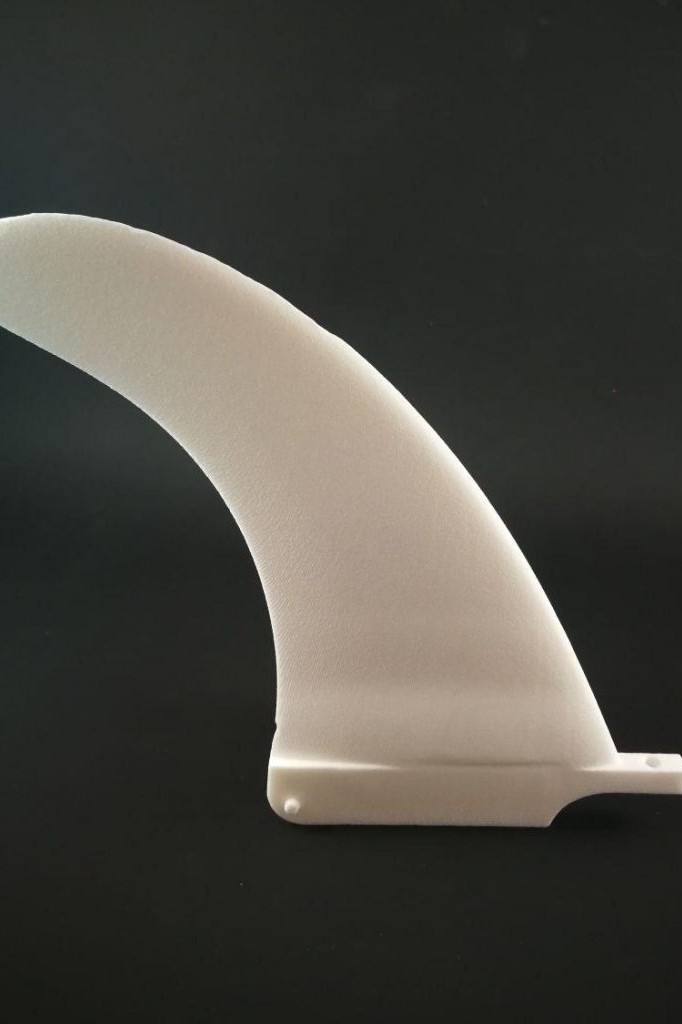

We were approached by a surfing customer with a request to restore the surfboard fin. For this purpose, we performed 3D scanning and 3D printing of the original fin. We used our most accurate 3D scanner “Artec Space Spider”. 3D point accuracy of this device is as high as 0.05 mm, so the entire geometry of the fin was captured with extreme precision. For 3D printing was used SLS technology printer and PA2200 material. Nylon is an extremely strong and durable material. Due to all its features, it is perfect for replacing the original surfboard fin.

3D scanning and 3D printing not only allowed the customer to get a copy of the required part very quickly but also saved him money. This fin can be bought only from stores abroad, so by summing up the price and delivery of the product, the customer was happy to save his money by choosing 3D technologies.

3D printing technology: SLS (Selective Laser Sintering)

3D printing material: PA2200

Size (mm): 210 x 14 x 190