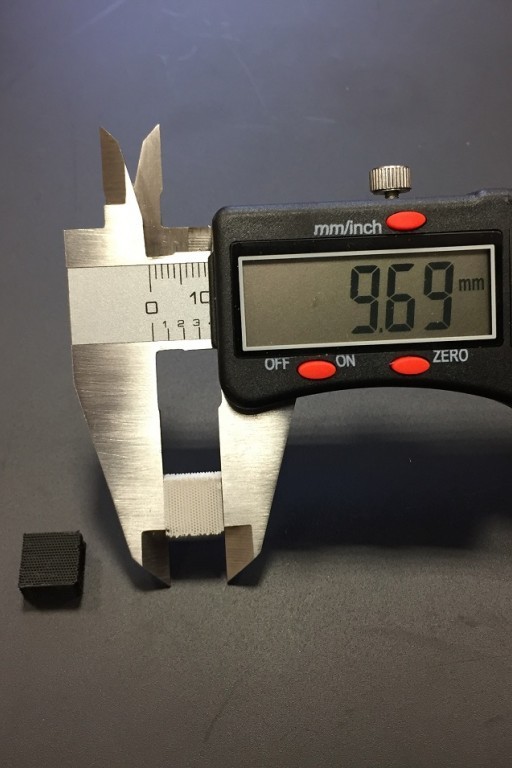

Small cubes were printed according to the customer request to evaluate FDM (fused deposition modeling) printers micro print and precision capabilities. The prepared model was in the form of a grid, where the distance between beams reached only 0.3 mm and the width of the joists was only 0.2 mm.

The main goal was to evaluate exactly how the printer extruded the plastic and how precisely the positioning head is located. Any bigger deviation would adhere to adjacent print strands.

These cubes were printed by using the Mass Portal company’s printer with a 0.2 mm nozzle (FDM’s standard printer nozzle is 0.4 mm). In practice, FDM printers created on a delta robot basis are characterized by speed, positioning accuracy, and even (“clean”) movement. Of the few FDM printers used in this experiment, only the Mass Portal serial device was able to print the desired grid.

A microscope magnified 80 times was used for precise evaluation. Cubes were printed with a thickness of 0.1 mm. The first photo is made from the top and there is visible that the beam thickness is deviating within 30 microns from the original size, the gap between beams reaches 35 microns more. The second photo is from the side to show the joints of the layer. Since it was decided to print with a thickness of 0.1 mm, the printer had to lay two beams to get the pattern shown in the 0.2 mm beam width and the deviation was only 9 microns. The distance between beams is 23 microns, the thickness of the layer is 3.5 microns.

The results of this experiment suggest that the deviations are very minimal and the main factor was the uneven plastic wire diameter. Despite the unevenness of the plastic wire, only “Mass Portal” series printer prints this cube nicely.