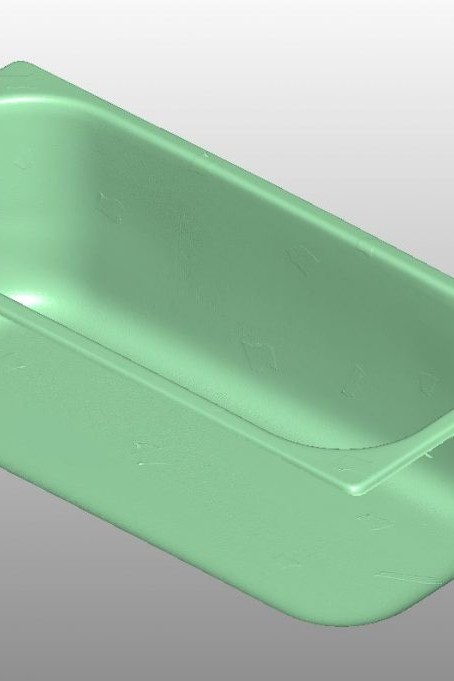

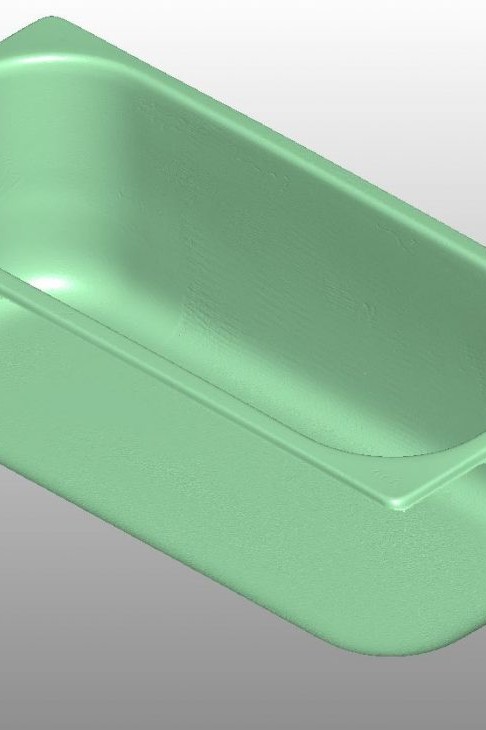

3D scanning is a great tool in the measurement process, especially when it comes to sleek geometry, convex surfaces. This time, we were contacted by a company intending to purchase metal ice cream refrigeration bowls but wanted to make sure the quality and accuracy of the products. We were asked to perform a 3D scanning of these stainless steel ice cream bowls. For this purpose, the same ice cream bowls were produced by three different manufacturers and were given to us. At the customer’s request, they were scanned in up to 0.05 mm accuracy, which is impossible with manual measuring devices.

The “Artec Space Spider” 3D scanner was used for fast and precise scans in the scanning process. The inner surfaces of all three bowls were scanned. The client performed a comparative analysis for bowls, which showed that one of the bowl deviations are too large. 3D scanning has also made it easier for the final supplier to choose – the products were ordered from the most precise bowl manufacturing company. Later, according to the available information, the frames into which the new bowls will be placed were modeled. For this aim was used reverse engineering method.

“Artec Space Spider” 3D scanner ensures up to 0.05 mm accuracy, making 3D scanning services extremely accurate with the highest quality.

Size of the object (mm): 360 x 165 x 120