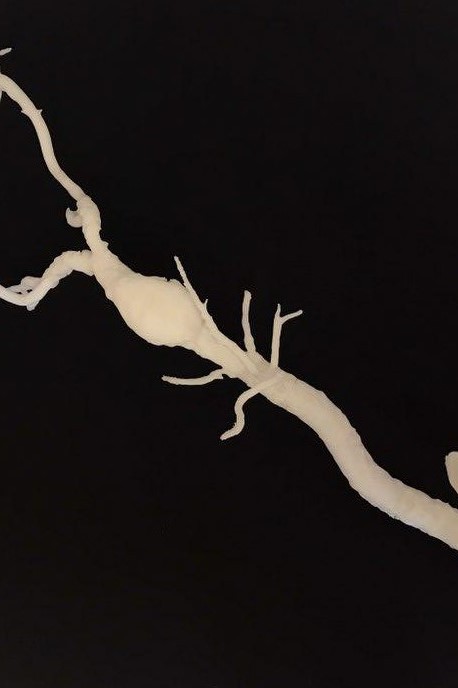

A client who is engaged in in-vitro medical solutions, after submitting a computer aortic 3D model, printed a human aortic model.

According to the 3D computer model, the “Zortrax M200”, the most advanced FDM 3D printer, prints a partially divided model of high-quality ABS plastic to assess the strength required. The post-printing process took place in several stages, in which support structures were removed from complex locations and glued to a single, seamless pattern.

3D printing technology implements the production of customized layouts with less time and financial costs compared to traditional production methods and meets precision requirements with micron accuracy. Large format 3D printing does not limit the size of the product and allows for full compliance.

3D printing material: ABS

3D printing technology: FDM (fused deposition modeling)

Product size (mm): 669 x 309 x 195