It’s not a secret that many people are always striving for exclusivity. Uniqueness is especially popular these days as well. And whether we’re talking about fashion trends or interior solu- tions. The production of unique products is limited to small production runs, so it is especially important here to choose the optimal production method that allows maintaining a reasonable product price.

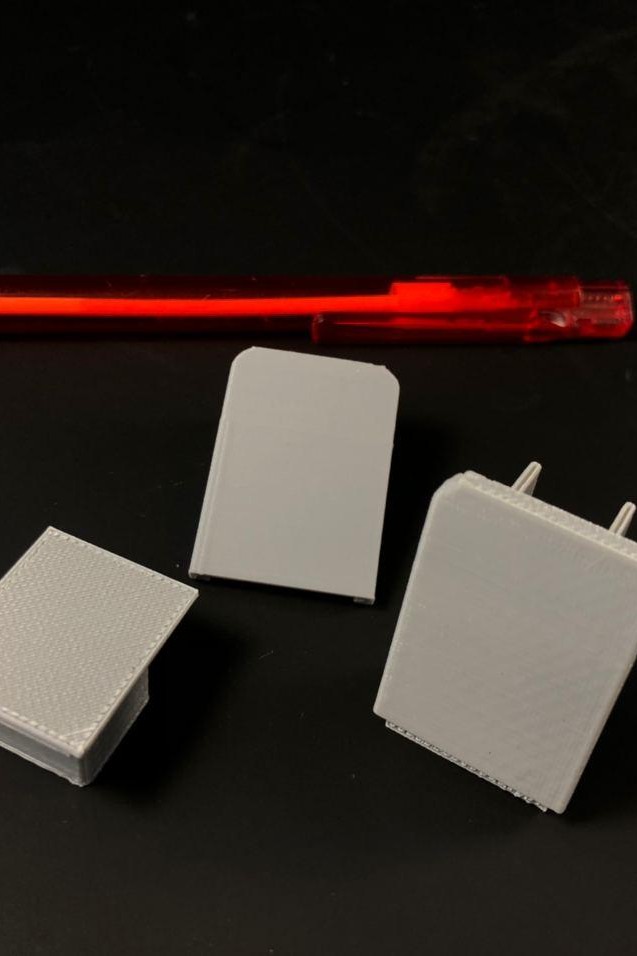

Companies dealing with non-standard bathroom solutions are no exception. At the request of one of them, we did 3D printing of 500 pcs structural shower enclosure details. To realize this order, we use very popular and recognized “Zortrax M200” 3D printers. The printing was made of extremely strong and durable ABS plastic. Using our production capacity, we fulfilled the order in just 5 working days.

This method of production allowed very quickly and at low cost produce these parts for shower enclosures. 3D printing is a great way to combine production speed and optimal product prices.

3D printing technology: FDM (Fused Deposition Modeling)

3D printing material: ABS

Size (mm): 13.00 x 26.15 x 37.93 and 26.40 x 11.80 x 22.40