3D technology is a great way to recreate rare or even discontinued objects. 3D technologies are great for that. The benefits of 3D scanning and 3D printing have already been convinced by many of our customers.

This time we are sharing a pressure equipment part recovery project. We were approached by a customer who has an old, worn-out part, which is no longer possible to buy on the market.

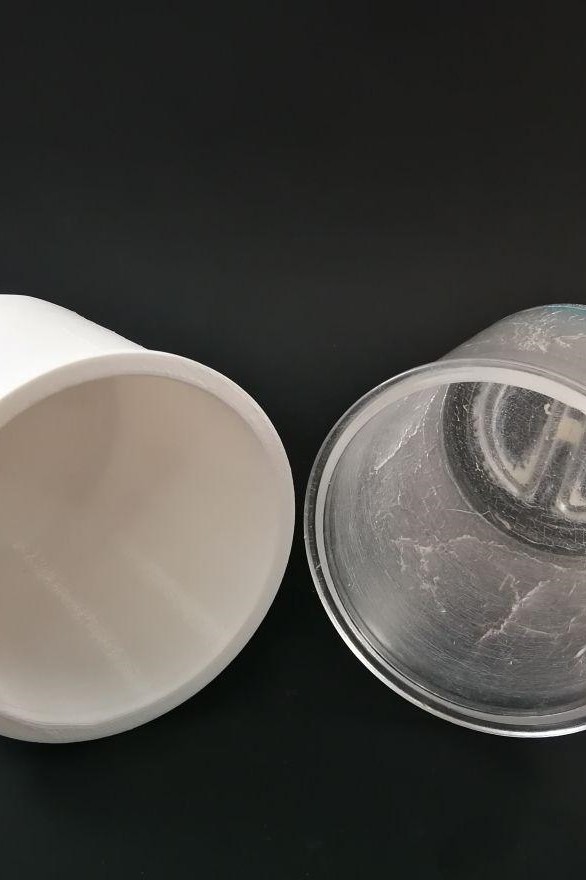

The special plastic jar settles into the specific machine and must withstand the appropriate pressure.

We scanned the old and cracked jar with a high-precision “Artec Space Spider” 3D scanner. The scanned 3D model was adjusted and aligned to fit the machine perfectly. We printed this 3D model with an extremely fast and accurate “Prusa” 3D printer based on the principle of FDM technology. The printed part will come into contact with various liquids, therefore we chose one of the most chemically resistant plastics for printing – PETG.

This combination allowed the customer to get a part that no longer exists on the market in a particularly fast time and thus save money without buying a new machine.

3D printing technology: FDM (Fused Deposition Modeling)

3D printing material: PETG

Object size (mm): 100.00 x 100.00 x 110.00