Reverse engineering is becoming more and more popular type of 3D modeling in which a computer parametric 3D model is created using an original part. It is the most efficient and effective way to create a CAD model of a real physical object of any shape using data obtained during the 3D scanning. Using the most innovative 3D scanning equipment, we can turn your parts into digital 3D CAD models, which can be further used for modifications or computer modeling.

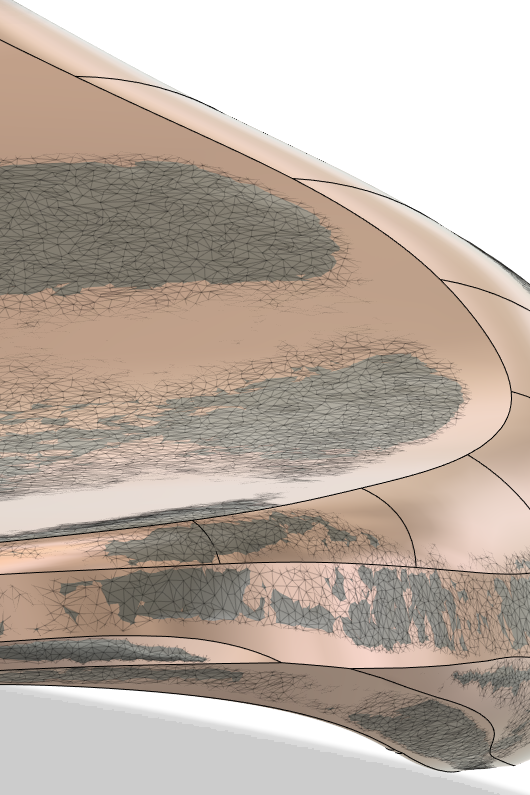

Reverse engineering can be applied not only to standard but to particularly complex and organic-shaped parts as well. One of such example is this molded foam part of a chair. According to the customer’s request, we performed this product 3D scanning and parametric STEP file preparation. For 3D scanning we used the most advanced 3D scanner “Artec Leo” with an integrated processor and large field of view. Due to the exceptional features of this scanner, the digitizing of flexible foam was performed extremely quickly and accurately. Scanning 3D point accuracy is up to 0.1 mm.

The 3D scanned data was used to prepare the STEP model of the product. This file can be used to improve product design, create molds, perform simulations, visualizations, prepare files for 3D printing, milling, cutting, or documentation purposes.

Size (mm): 484.45 x 170.43 x 277.24