3D Modeling

More and more customers are discovering the benefits of 3D technology, so the need for 3D modeling is greater than ever. Our company provides 3D modeling and reverse engineering services with globally recognized CAD (Computer-Aided Design) and Digital Sculpting technical software.

Based on the provided 2D drawings, photos, sketches or ideas, highly qualified modelers and designers create the 3D model to meet your needs, work on designs and help implement the solution.

Why choose our services

- Free consultations and project evaluation

- Modeling based on listening to the customer’s needs

- Experienced and highly-skilled engineers and designers

- Practical experience with 3D scanning and 3D printing

- A large number of successfully completed projects

- Wide range of modeling services

- The possibility to perform both modeling and production of a product in one place

CAD Modeling

This is one of the most commonly used 3D modeling techniques when computer programs are used to create a 3D model of the required part. Modeling can be performed based on customer sketches, drawings, provided examples, or photographs. The created 3D model is suitable for various production methods, such as 3D printing, milling, cutting, etc. Having a CAD model, it is possible to perform computer simulations of the designed part and testing in the future. Depending on its format, the model can be adjusted and improved according to the customer’s needs. Available formats: .stp, .step, .3dm, .igs, .iges, .obj, .stl and others.

Preparation of DWG drawings

Based on the 3D model created by us or provided by the customer, 2D drawings, which are very often used for various production methods or documentation, can be prepared. The drawing provided by us has all the necessary projections and dimensions. It is also possible to export only the vector lines in DWG or DXF formats, which are required for file preparation on CNC, laser, plasma, water jet cutting, or other machines.

Rendering visualizations

It is an easier way to imagine how an object created on a computer would look like in reality. We create realistic, colorful visualizations by applying the desired colors and textures to the 3D modeled objects, placing them in the required environment, etc. To create visualizations, it is necessary to have a computer 3D model made by us or provided by the client.

Digital sculpting

Using world-renowned digital art modeling softwares, we create artistic 3D models, fully restoring their realism and accuracy to the level you need. We model sculptures, people, buildings, layouts, awards, we can create a product design or recreate your desired artistic object based on the provided photos or sketches.

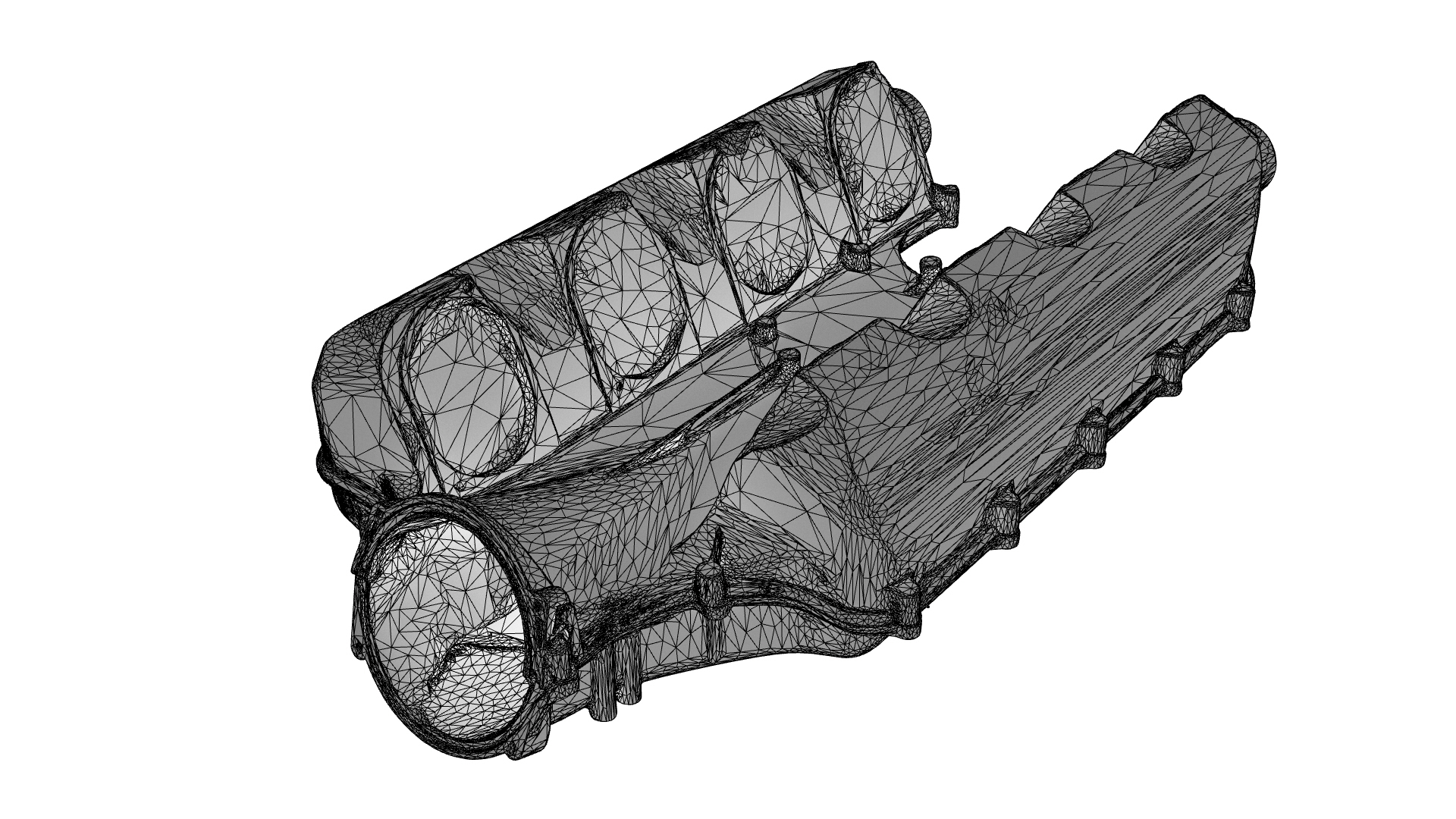

Reverse engineering

It is the most efficient and effective way to create a CAD model of a real physical object of any shape using data obtained during the 3D scanning. Using the most innovative 3D scanning equipment, we can turn your parts into digital 3D CAD models, which can be further used for modifications or computer modeling.

Reverse engineering model types

Our reverse engineering services can be divided into 3 main types according to the file categories. Since every project is different, each client’s file is modeled to meet the exact requirements of the customer.

Parametric

The parametric model is used when future model corrections are intended to be made, 2D drawings are required, the surface treatment must be smooth (during the production), and when other parts of the mechanism are on/around the part.

- An accurate model created by converting carefully scanned data

- Original part defects can be ignored or incorporated

- A solid parametric model

- The possibility to modify the model parametrically

Hybrid surface

The model of hybrid surfaces is used when it is intended not to adjust or very slightly adjust the model in the future when 2D drawings are required, the surface treatment must be smooth (during the production), and when there are other parts of the mechanism on/around the part.

- An accurate model created by converting carefully scanned data

- Original part defects can be ignored or incorporated

- “Dumb” IGES/STEP format surfaces

- Modifications require re-trimming

Organic surface

The organic surface model is used when a precise part is required, including all lesions and irregularities, when it is intended to design parts that perfectly match the shape of the part (including all irregularities), surface treatment is not essential, and surfaces are organic, such as tooth surfaces, bones, sculptures, specifically adapted shapes, etc.

- The model is restored to look exactly like the original

- All original part’s defects are shown

- Patch-work of small surfaces

Using our reverse engineering services will allow you to:

- Have a CAD model that captures the original part design

- Design a new part that matches the old one

- Accurately model operating surfaces

- Make changes or improve the design of the part at any time

- Remodel the part without original part defects

- Modernize the production process

Our reverse engineering services are focused on:

- Automotive

- Industrial equipment

- Aircraft

- Ship

- Furniture

- And other engineering industries